BLOG

7 Reasons to Work with Our AS9100 Machine Shop

Remember when we shared that we were in the process of getting AS9100 certified? Well, we’re thrilled to announce that Focused on Machining is now officially an AS9100 machine shop!

Top Shops data indicates that only 45% of machine shops have quality certifications like ISO 9001 and AS9100, and we’re proud that our Denver machine shop is part of this elite group.

Remember when we shared that we were in the process of getting AS9100 certified? Well, we’re thrilled to announce that Focused on Machining is now officially an AS9100 machine shop!

Top Shops data indicates that only 45% of machine shops have quality certifications like ISO 9001 and AS9100, and we’re proud that our Denver machine shop is part of this elite group.

Being AS9100 certified means that we follow a strict set of quality management system requirements to ensure that we provide safe and reliable parts to aerospace customers.

We already have loads of experience machining aerospace prototypes. But this certification will allow us to deepen our relationships and work with customers on low-volume production runs as well.

How Customers Benefit from Working with Our AS9100 Machine Shop

Customers across all industries benefit from working with an AS9100 machine shop. In preparation for this certification, we’ve honed our processes and operations to provide better service than ever. Here’s what you can expect from Focused on Machining:

Comprehensive documentation. Formal inspection reports are an industry standard for aerospace. But no matter what industry you’re in, your parts will benefit from going through our full quality process. Rather than limiting this process to only the customers who require inspection data, we conduct inspections and formally document the results for each part we machine. We also generate first article inspection (FAI) reports as part of this process.

Formal PO confirmations. When we confirm a date and price to a customer, we’re dead set on delivering on those promises no matter what. Before confirming a PO, we conduct due diligence to verify things like material pricing and availability and overall project timeline. Our goal is to always negotiate upfront with customers instead of flying by the seat of our pants and having to negotiate on the back end.

Part tracking. With the click of a button, our comprehensive ERP system tells us exactly where a part is in the manufacturing process—whether it’s in machining, inspection, outside processing, or ready to ship. We can provide full visibility into anything from the amount of time spent on the part to the machine it’s currently on. All you have to do is ask.

Detailed box labels. We take pride in our box labels, which include a clear image of the part and key details like revision number, work order number, quantity, and more. Many customers have told us that these box labels help streamline their own receiving processes. One customer even uses our packaging as part of their inventory system because it has all the information they need.

No paper trails. We store all data digitally in our secure ERP system. You never have to worry about your proprietary information floating around our shop.

Serialization. An increasing number of customers have been asking us to serialize their parts and we’re more than happy to deliver. Our machinists track and number each part sequentially and can even laser engrave part numbers at your request.

Faster turnaround. As a result of our streamlined processes, we’re working more efficiently than ever before. Although material shortages are slowing down everyone in manufacturing right now, we remain committed as ever to our promise of high-quality CNC machined parts when YOU need them.

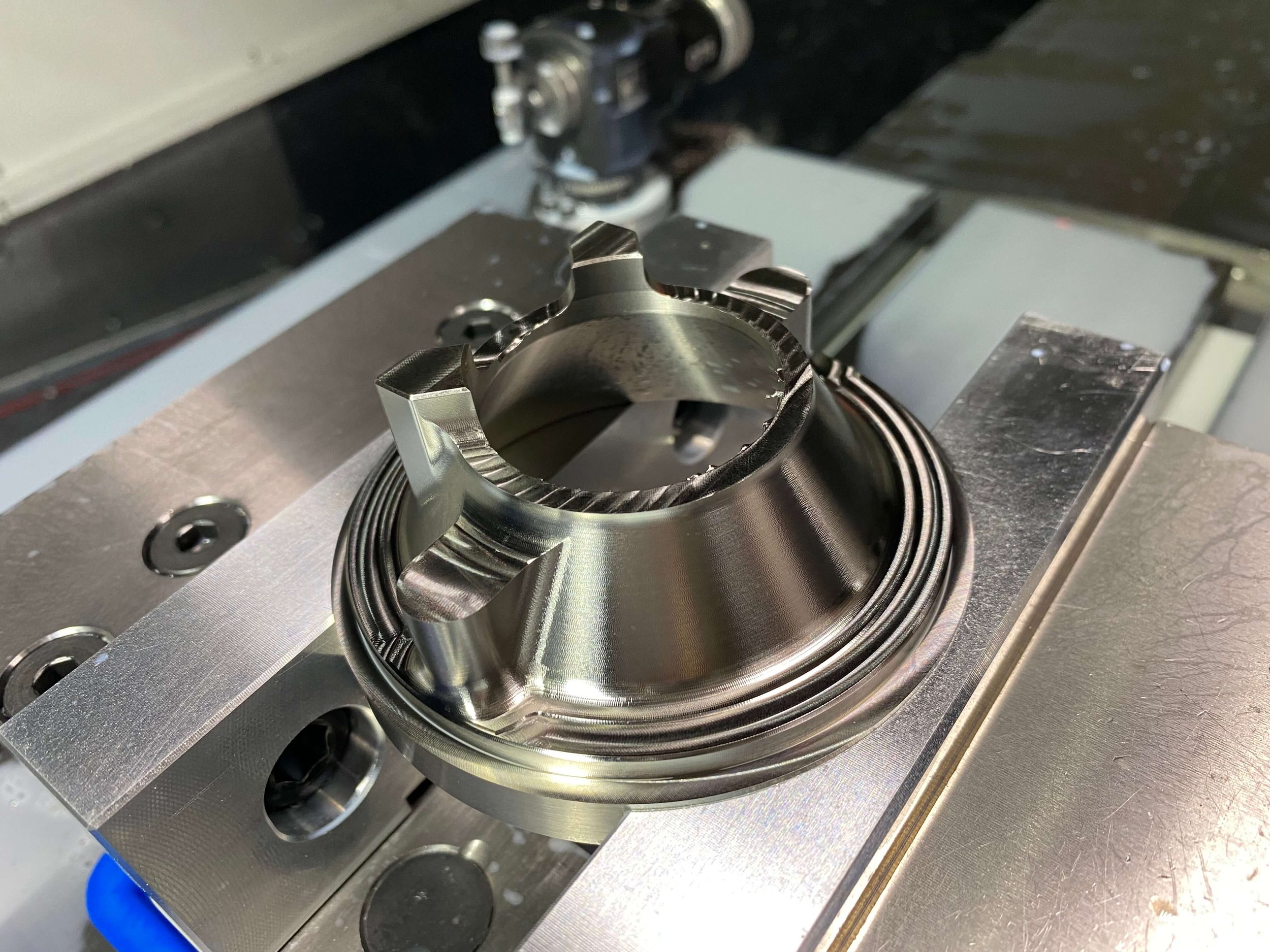

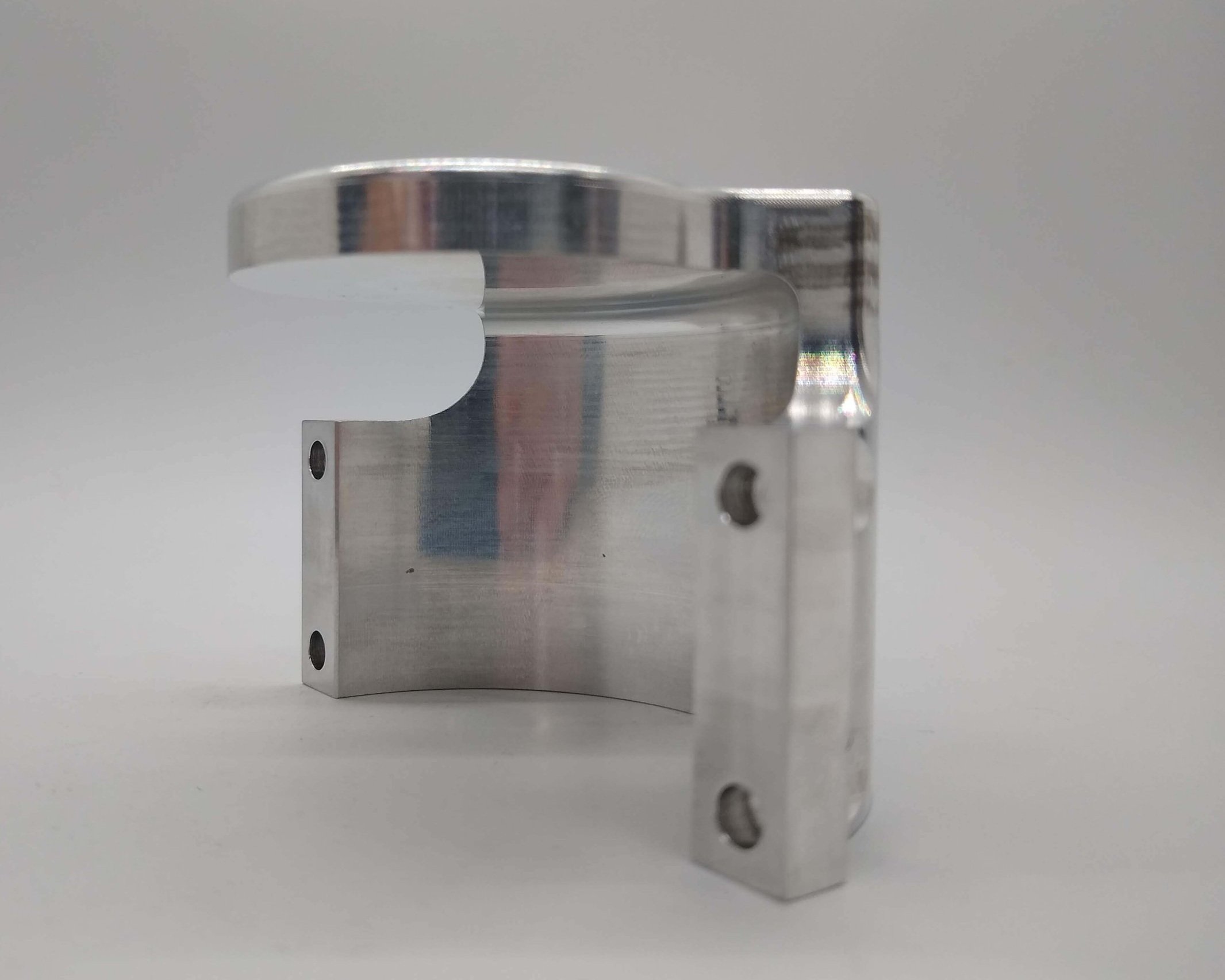

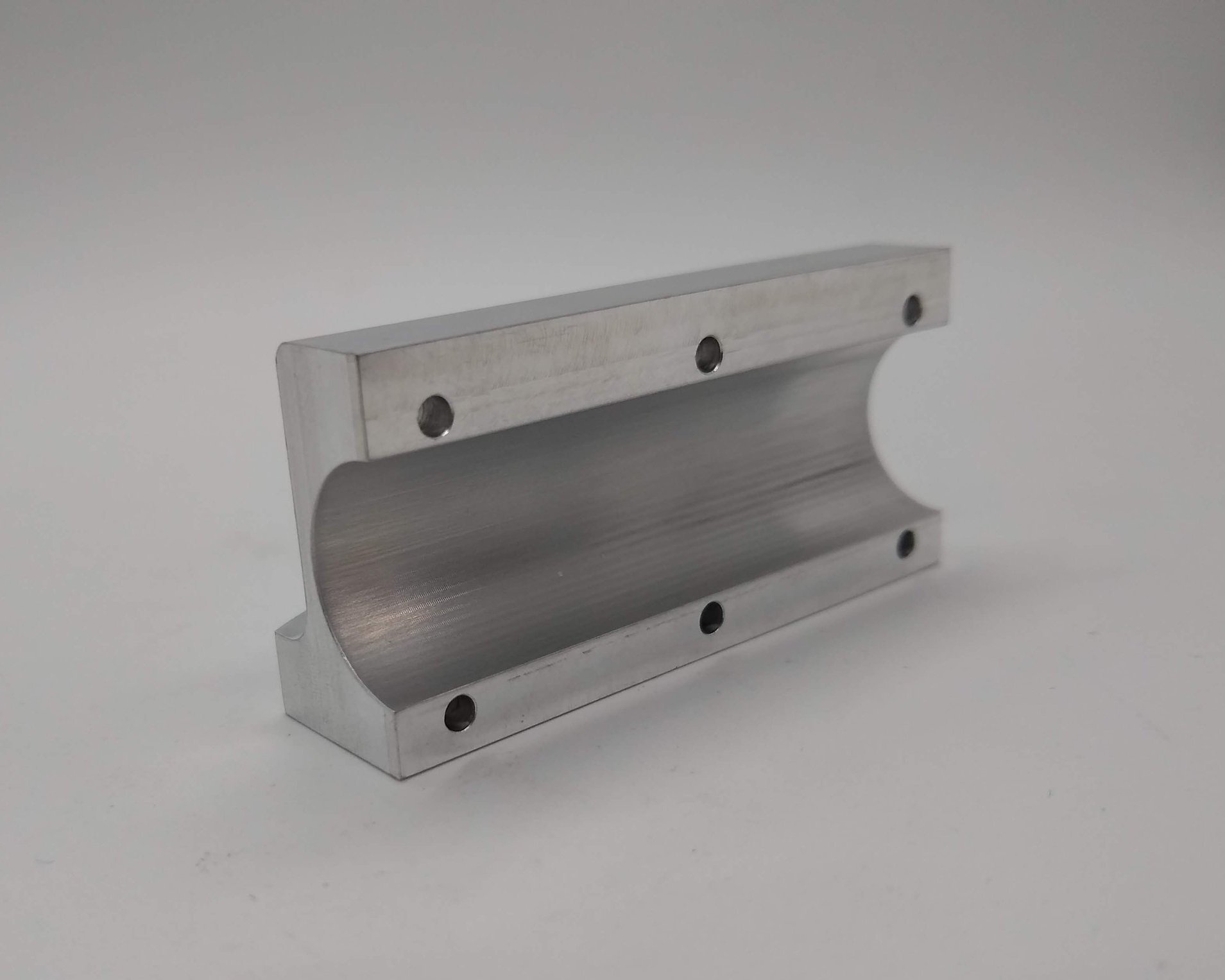

For us, the best thing about being an AS9100 machine shop is that it gives us the opportunity to take on more of the aerospace machining projects we love most—from complex titanium parts to internal and external components for Nitronic 60 minisatellites.

Here’s a look at some of the aerospace parts we’ve made recently:

Focused on Machining is ready and excited to put our aerospace machining expertise to the test for you. If you’re looking for a reliable AS9100 machine shop, we hope you’ll trust us with your part.

Nitronic 60 Stainless Steel: The Next Frontier in Space Materials

At Focused on Machining, we’re always up for the next challenge that comes our way. From cracking the code on titanium machining to pursuing AS9100 certification, we’re masters of complexity and difficulty in all aspects of our precision CNC machining services.

At Focused on Machining, we’re always up for the next challenge that comes our way. From cracking the code on titanium machining to pursuing AS9100 certification, we’re masters of complexity and difficulty in all aspects of our precision CNC machining services.

When confronted with a new material, our philosophy is always this: just because we’ve never cut it before doesn’t mean we won’t. So when quotes for Nitronic 60 parts started hitting our inbox, we jumped at the opportunity to work with this innovative material that’s generating a lot of buzz in the space industry.

Now, we’re well-versed in the intricacies of Nitronic 60 machining. Through our experience and our investment in optimal tooling, we’re able to maximize speed and precision, always delivering excellent results.

What Is Nitronic 60? Nitronic 60 is an all-purpose stainless steel alloy fortified with silicon and manganese to provide these key benefits:

High corrosion resistance. Nitronic 60 has corrosion resistance properties comparable to 304 and 316 stainless steels while offering nearly twice the yield strength.

Minimal wearing, galling, and fretting. The addition of silicon and manganese gives this material superior wear-inhibiting properties compared to other types of stainless steel. While threaded 304 stainless steel parts tend to gall and grip onto each other, Nitronic 60 parts go together much more smoothly, making it popular for helical thread inserts in high-performance applications such as aerospace.

Temperature performance. Nitronic 60 maintains its mechanical properties across a wide temperature range, including extremely elevated temperatures.

These benefits are especially important in space applications, where parts are continually subjected to extreme environments and temperature changes. Our extensive aerospace machining experience ensures we can manufacture Nitronic 60 components to the exacting requirements of space applications.

The choice between Nitronic 60 and other high-performance materials depends on the specific demands of the application. For instance, in cases where galling resistance is critical, Nitronic 60 often outperforms alternatives like Alloy 333. However, applications prioritizing corrosion resistance might call for 316 stainless steel (also known as "316 surgical steel" for its medical applications), while those requiring exceptional high-temperature performance might be better served by Inconel 718.

Whatever your material requirements, our team at Focused on Machining brings extensive experience to every project, including specialized expertise in Inconel machining.

At Focused on Machining, we’re always up for the next challenge that comes our way. From cracking the code on titanium machining to pursuing AS9100 certification, we’re masters of complexity and difficulty in all aspects of our precision CNC machining services.

When confronted with a new material, our philosophy is always this: just because we’ve never cut it before doesn’t mean we won’t. So when quotes for Nitronic 60 parts started hitting our inbox, we jumped at the opportunity to work with this innovative material that’s generating a lot of buzz in the space industry.

Now, we’re well-versed in the intricacies of Nitronic 60 machining. Through our experience and our investment in optimal tooling, we’re able to maximize speed and precision, always delivering excellent results.

What Is Nitronic 60?

Nitronic 60 is an all-purpose stainless steel alloy fortified with silicon and manganese to provide these key benefits:

High corrosion resistance. Nitronic 60 has corrosion resistance properties comparable to 304 and 316 stainless steels while offering nearly twice the yield strength.

Minimal wearing, galling, and fretting. The addition of silicon and manganese gives this material superior wear-inhibiting properties compared to other types of stainless steel. While threaded 304 stainless steel parts tend to gall and grip onto each other, Nitronic 60 parts go together much more smoothly, making it popular for helical thread inserts in high-performance applications such as aerospace.

Temperature performance. Nitronic 60 maintains its mechanical properties across a wide temperature range, including extremely elevated temperatures.

These benefits are especially important in space applications, where parts are continually subjected to extreme environments and temperature changes. Our extensive aerospace machining experience ensures we can manufacture Nitronic 60 components to the exacting requirements of space applications.

The choice between Nitronic 60 and other high-performance materials depends on the specific demands of the application. For instance, in cases where galling resistance is critical, Nitronic 60 often outperforms alternatives like Alloy 333. However, applications prioritizing corrosion resistance might call for 316 stainless steel (also known as "316 surgical steel" for its medical applications), while those requiring exceptional high-temperature performance might be better served by Inconel 718.

Whatever your material requirements, our team at Focused on Machining brings extensive experience to every project, including specialized expertise in Inconel machining.

The Growing Demand for Nitronic 60 Minisatellites

Nitronic 60 is commonly found in minisatellites, which are popular right now in the space industry. With private companies like SpaceX, Blue Origin, and Virgin Galactic enmeshed in a modern-day space race, there’s a unique opportunity for these toaster-sized minisatellites to hitch a ride into space for much cheaper than ever before. Manufacturers of minisatellites are essentially piggybacking on a trip to space that has already been paid for. Pretty smart!

So far, our AS9100 machine shop has made both internal and external components for these minisatellites using Nitronic 60. We also just finished precision machining for a part that will attach to a Mars rover.

If you have any Nitronic 60 projects coming down the pipeline, we hope you’ll consider getting a quote from Focused on Machining. Our appetite for complexity makes us the perfect partner for new and difficult materials that many other machine shops no-quote. We’re also committed to meeting stringent deadlines no matter what it takes.

Request a quote today from our Colorado machine shop for your next Nitronic 60 project!

Frequently Asked Questions

What is Nitronic 60 material equivalent to?

Nitronic 60 offers oxidation resistance comparable to Type 309 stainless steel and significantly better than Type 304 stainless steel. This alloy is renowned for its exceptional resistance to wear and galling.

What is the difference between Nitronic 60 and Inconel?

Nitronic 60 is a high-strength stainless steel known for wear, galling, and corrosion resistance in moderate temperatures. In contrast, Inconel, a nickel-chromium alloy family, excels in extreme heat and oxidation resistance, making it ideal for high-temperature applications like jet engines and turbines.

Can Nitronic 60 be welded?

Nitronic 60 can be welded with standard methods, but proper techniques are crucial. Use Nitronic 60, 309, or 310 fillers for high strength, and low heat input with convex bead profiles to prevent cracking. Avoid excessive weaving to reduce surface cracks.

Is Nitronic 60 magnetic?

Nitronic 60 is a non-magnetic stainless steel with low magnetic permeability, even when cooled to sub-zero temperatures or cold worked.

Cracking the Code on Titanium Machining

At Focused on Machining, we love working with titanium. . . seriously! Challenging jobs are the ones that get us up in the morning excited about coming to work. There’s nothing more satisfying for our team than figuring out how to excel at something really tough. In particular, we specialize in medium and high-volume production machining services for titanium projects.

Last updated July 2025

Tired of machine shops no-quoting you on complex titanium parts? You need a shop that knows what it takes to machine this difficult material.

At Focused on Machining, we love working with titanium. . . seriously! Challenging jobs are the ones that get us up in the morning excited about coming to work. There’s nothing more satisfying for our team than figuring out how to excel at something really tough. In particular, we specialize in medium and high-volume production machining services for titanium projects.

As part of Colorado’s booming aerospace industry—the second-largest in the country!—our precision machine shop is proud to be a go-to manufacturing partner for titanium aerospace parts.

Challenges of Titanium Machining

Let’s take a quick look at why many shops avoid titanium machining:

It’s difficult to source. Most shops have a close network of local vendors that they rely on for purchasing material in standard bar form. Titanium, however, is much more difficult to source. Shops that work with titanium must look beyond local vendors to source the material out of state, often paying for additional expenses like shipping and freight charges and having the material cut to piece size.

At Focused on Machining, we have a variety of suppliers that deal exclusively in titanium, and we are constantly discussing pricing, lead times, and delivery with them to stay on top of the market.It’s difficult to machine. When machine tools aren’t sharp enough, titanium tends to get gummy during machining, which can lead to a problem known as work hardening. The dull tools mush the material, in turn creating friction and added heat—a known enemy of machinists. The introduction of heat makes what’s already a hard material even harder, increasing the risk of tool wear and compromising the quality of a part.

It’s difficult to figure out. Any challenging machining process inevitably comes with a learning curve. Once you crack the code, there’s an element of repeatability that simplifies processes going forward. But the simple truth is that a lot of shops don’t want to invest the time and effort to reach that point.

Why Focused on Machining Excels at Titanium Machining

We’re not like other shops. We’re always bettering ourselves to become better for our customers. Here’s how we cracked the code on titanium machining:

Tooling selection. In precision machining for materials like steel or aluminum, any 3- or 4-flute end mill—new or used—will cut through the metal just fine. But that’s not the case with titanium. When we work with titanium, we use brand new high-performance 5-flute to 7-flute end mills every time. We’ll never throw a used end mill at a machine to cut titanium. This tooling expertise allows us to drastically increase cutting speeds, reaching nearly the same rate as we do with aluminum parts.

Careful monitoring. Since sharp tooling is the key to avoiding work hardening, we monitor machines closely for tool wear—especially when we’re doing production jobs. If necessary, we change the end mill out much earlier than we normally would to ensure consistently sharp cutting.

Updated technology. We’re pushing the envelope on speeds, rigidity, and tooling performance with a fleet of advanced machines less than 10 years old. Our machines are so fast that we can cut titanium almost as quickly as we can cut aluminum. That’s 180”-250” per minute!

Appetite for complexity. Unlike many of our competitors, our Denver machine shop seeks out challenging parts. If two quotes come in at the same time and one of them is a complex titanium aerospace part, you can guess which one we’re more excited about. We enjoy being the solution to our customers’ toughest machining challenges.

Vendor network for outside processes. Our trusted vendor network allows us to connect you with the right match for your project, including access to specialized options like Tiodize processes—proprietary surface treatments similar in function to anodizing that improve wear resistance and corrosion protection. We can even maintain tight tolerances of +/-0.001" after hard anodizing, a challenge requiring trusted vendors and extremely clear communication throughout the process.

Titanium is a critical material for many of the industries we serve, especially aerospace and defense in our work as an AS9100 machine shop. Major projects in the coming years will require substantial quantities of titanium parts, and we're well-positioned to support you as a tier-one OEM supplier.

Next time you need machined titanium parts, save yourself the hassle of a bunch of no-quotes and come to Focused on Machining first. Request a quote today!

How Focused on Machining Is Preparing for AS9100 Certification

We’re excited to share that we’re in the process of getting AS9100 certified here at Focused on Machining! As we build our reputation as a leading aerospace manufacturer, this certification will allow us to make parts for aircraft that house or transport humans.

We’re excited to share that we’re in the process of getting AS9100 certified here at Focused on Machining! As we build our reputation as a leading aerospace manufacturer, this certification will allow us to make parts for aircraft that house or transport humans.

Being AS9100 certified means following a strict set of quality management system requirements designed specifically for the high-stakes aerospace industry.

In addition to building our aerospace customer base, we’re proud to show customers in all industries that we’re the best Colorado CNC machine shop around. We’re always willing to jump through hoops to better ourselves—and our customers reap the benefits.

Today, we’re pulling back the curtain to reveal exactly what we’ve done to prepare for AS9100 certification and what these changes mean for our customers.

Preparing for AS9100 Certification at Focused on Machining

Here’s a look at some of the upgrades we’ve made internally during the AS9100 certification process:

Tightening up our targets. Guaranteeing on-time delivery, exceptional product quality, and a low scrap rate is nothing new for our Denver machine shop. But we’ve tightened up our targets more than ever. And we’re tracking, reporting, and auditing these goals regularly to hold ourselves accountable. We even created a new target to speed up how quickly we confirm orders once they’ve been placed.

Implementing a new inspection process for receiving materials. This new process dictates how we identify and segregate materials in-house. We’ve always incorporated some identification and segregation measures. But now we’re being exceptionally diligent with these efforts. There’s no more intermingling of materials like there once was. We also have a segregated shelf in our shop where we send all materials that we can’t immediately certify or trace.

Streamlining how we provide inspection data to customers. With our new process in place, we can easily provide any level of inspection data our customers need. Whether it’s one feature on every part, all features on one part, all features on a couple of parts, or all features on all parts, we can get the information they need with a couple clicks of a button.

Installing a new CMM. We recently finished calibrating our new CMM, which is even better quality than the machine we were previously using. We now have the capability to inspect parts at a higher level of accuracy than ever before.

When We Better Ourselves, We Become Better for Our Customers

How do the changes we’ve made impact our customers? It’s a great question, and we’re more than happy to answer it:

Full documentation of inspection capabilities. Previously, if a customer didn’t require First Article Inspection or other documentation, we’d check their parts to ensure quality but didn’t create formal documentation. Now, we document everything. If you come to us later in the process looking for a report you didn’t request initially, we can provide it quickly and easily.

Better material traceability. We’re intent on reducing non-traceable materials as much as possible. If you ever want to know the details about a material, we can get you certifications showing the mill it came from, the chemical makeup, where it was made, and more.

Proficiency at machining complex parts. Tired of other shops no-quoting you? We make complex parts other shops don’t want to make, and work with challenging materials they’d rather not deal with. We love parts that have 20+ features. And if your tolerances need to be tighter than industry standards, like +/-.0002”, we’ve got you covered.

Higher on-time delivery rate. We know how critical lead times are for our customers, so we aim for an on-time delivery rate of 95% or higher. The bottom line is that you can always expect us to be on time. If for any reason we aren’t, we’ll analyze our processes to see what went wrong and figure out how to prevent it from happening next time.

Leaner and more accurate quoting. We have extremely robust processes in place to help us achieve our 5% scrap rate target. If we end up with even a few bad parts out of 100, we identify how we can fix these mistakes going forward. That way, when we make those same parts again, we can be even more precise and consistent. Maintaining a low scrap rate allows us to be lean and accurate with our quoting, both in terms of time and material.

Stay tuned for more updates on our AS9100 certification progress! In the meantime, if you’d like to work with one of the best machine shops in Colorado, go ahead and request a quote!

Top 7 Ways You Might Be Overengineering Your Precision CNC Machined Parts

Engineers are under so much pressure to design properly functioning parts that they often fall into the trap of overengineering. The trouble is that overengineering inevitably increases cost and lead time on the machine shop floor.

Last updated June 2025

Engineers are under so much pressure to design properly functioning parts that they often fall into the trap of overengineering. The trouble is that overengineering inevitably increases cost and lead time on the machine shop floor.

At Focused on Machining, we have a simple philosophy about complex parts: “If you need a part machined a certain way, we’re happy to do it for you. But if your materials, features, or tolerances aren’t necessary for the function of the part, we can save you serious time and money.”

We always like to check in with customers during the quoting phase because a conversation gives us a far better understanding of a part than a drawing or model. During these conversations, we often identify cost and time-saving opportunities that can be achieved simply by making a part slightly less complex.

Today, we’re uncovering some of the common ways customers overengineer parts to help make you aware of these factors during the design phase.

7 Ways Customers Overengineer Parts

1. Making the tolerances too tight.

Tolerancing a feature to .002” or less indicates to our Colorado CNC machine shop that the feature is extremely critical. When a tolerance is that tight, we know that we need to really take our time, slow down our machining processes, and use fresh tools. But going slower and using higher-end tools in tight tolerance machining increases the cost and lead time of a part.

If you don’t want to pay more than what’s necessary, and your tolerances don’t have to be quite so tight, consider keeping tolerances at .005” or higher.

2. Adding complex features that have no functional value

It’s tempting to design a part that looks really cool. But keep in mind that complex aesthetic features like multifaceted surfaces are almost always challenging in precision machining. They may even require custom fixturing. Why spend more money than necessary for features that don’t improve part functionality?

3. Making walls too thin.

Since weight reduction is so important for aerospace applications, engineers will often design extremely thin walls to lightweight a part. This practice is especially common when designing the floor of a part.

But thin walls are more likely to warp, so any wall thickness measuring less than .06” creates risk in aerospace machining. And if you have exceptionally tight tolerances in addition to thin walls, the part will be even more challenging to make.

Unless you need extremely thin walls for the function of your part, we recommend keeping them over .06” so that they won’t easily bend or deform.

4. Choosing a finish your part doesn’t require.

Hard anodizing a part is risky because the process can cause dimensional changes significant enough to affect tolerances. If necessary, we’ll consider dimensional changes that can occur during this process before we begin machining. But if you don’t actually need hard anodizing, regular anodizing is much less likely to impact tolerances.

In some cases, anodizing may not be necessary at all. Many customers choose it by default to avoid leaving parts raw, but after a quick conversation, they often realize a chem film finish offers adequate protection with fewer tolerance concerns—and a lower cost.

If you’re not sure which metal finishing option is best for your part, we can help. Whether you’re considering anodizing, plating, or any other finish, we’ll guide you to the most functional and cost-effective solution.

5. Selecting materials that create more problems than they solve

Aerospace parts often wind up in such demanding environments that engineers may choose materials that are more high-powered than necessary. But just because a certain material theoretically exists doesn’t mean it’s easy to source.

If you’re concerned about thermal expansion because a part is going to Jupiter, you may understandably aim for a material with zero thermal expansion. However, if that material isn’t readily available (or available at all in some cases), there are alternatives. You can usually get comparable functionality from a material with very little thermal expansion that has been machined to the precise tolerances the part requires.

The challenges of material selection go far beyond aerospace applications. For example, we often see customers request UHMW because of the low price of the material. However, UHMW is so malleable that it can be difficult to hold even loose tolerances, often making machining a challenging and expensive process.

If you’re unsure which material is best for your part—whether you’re choosing between different aluminum grades, plastics, or exotic metals—we’re happy to talk through your application requirements.

6. Picking a harder material than necessary.

Stronger materials are inevitably more challenging to machine (they create more wear on the tooling). And yet, engineers will often pick a harder material than necessary, especially when it comes to stainless steel.

17-4 stainless steel, for example, comes in a series of different tempers based on the strength of the material. 17-4 stainless steel heat treated to condition H900 offers exceptional hardness. But 17-4 stainless steel heat treated to condition H1150 may provide sufficient strength for your application at a lower cost. Any opportunity to minimize heat treating will save you money.

7. Cramming too much data onto one page of a drawing.

This example is less about overengineering a part itself and more about how dimensions are presented.

As far as we’re concerned, there’s no such thing as too much information on a drawing. That said, some pages we receive are so packed full of dimensions that they’re actually difficult to decipher.

When dealing with complex parts in particular, it’s helpful to break your dimensions into 2-3 pages so that none of your important data gets lost in translation.

Bonus Tip: Match Your Hardware’s Precision to Your Part’s Precision

Here’s a situation we sometimes see: a customer sends us a part designed with extremely tight tolerances meant to house an off-the-shelf piece of hardware, such as a bearing. But when we check the hardware’s specifications, we find that it has a much looser tolerance.

In cases like these, we recommend matching precision with precision. Rather than over-machining a part to accommodate the hardware, it can be more effective to simply choose a higher-precision bearing.

Need Help? Let’s Discuss Your Next Part

At the end of the day, we’re always willing to provide custom CNC machining for exactly the parts our customers need. But we also like to help you save time and money whenever we can. Simplifying a complex part is often as easy as having a quick conversation, and it can have significant effects on the cost of production machining services for your project. So don’t be surprised if we reach out to discuss your quote!

Ready to work together? Request a quote from our Colorado machine shop and we’ll respond within 24 hours!

High-Quality Plating for CNC Machined Parts with Tight Tolerances

When machine shops need to achieve the tightest tolerances for parts, plating can make or break their ability to meet those specifications.

When machine shops need to achieve the tightest tolerances for parts, plating can make or break their ability to meet those specifications.

At Focused on Machining, we take this responsibility very seriously. We’ve been burned by plating shops in the past, and we won’t risk letting it happen again. That’s why we only work with the best platers in the country.

When you need your parts plated, you can count on us to select the right vendor, manage the entire process, and get your part done right the first time.

Why Is Plating CNC Machined Parts So Risky?

Tolerances are always measured post-plating. So we need to consider dimensional changes that may occur during this process before we begin machining.

Low-risk plating processes like adding a thin coating to an aluminum part won’t change the dimensions at all. But as the thickness of the plating increases, the part will inevitably grow. This growth can affect tolerances.

During regular anodizing, platers etch the part to remove a small amount of material before anodizing it. They typically replace only the etch of the part, moving it about 10% of our total tolerance. We have enough wiggle room with our tolerances that this minor part change usually isn’t a problem.

Hard anodizing is where plating gets really risky. The plater adds so much growth to the part that we need to account for it during machining to ensure that it’s the right dimension post-plating.

The Problem with Standard Plating Shops

Because plating is such a complex and scientific process, it’s difficult to get it right.

Plating consists of taking the parts, submerging them in a tank to clean them, transferring them to a tank of hot sulfuric acid, and calculating growth based on the surface area of the part.

But for some of the parts we make, it’s impossible to calculate the surface area. The temperature of the tank, the electricity going into the tank, and the consistency of both variables can change the growth rate of the material.

Plating shops need the right people and the right processes in place to achieve the tightest tolerances. Unfortunately, many of them have neither, so it’s impossible for them to guarantee consistency and precision.

Focused on Machining Guarantees High-Quality Plating for CNC Machined Parts

At our Denver machine shop, we won’t send your parts to just any plating shop. We have a well-vetted supply chain of vendors that we track and rate according to key performance indicators like quality and timing.

We’ll be honest with you, the best plating shops do have longer turnaround times of up to 6 weeks. Sometimes the cost is even a little higher. But in our experience making parts with exceptionally tight tolerances, it’s always better to get the parts right the first time.

If we send parts to a mediocre plating shop that rushes the process, there’s a good chance they won’t achieve the right tolerances and we’ll have to redo the entire order. We’ll never charge our customers extra money to make it right. But that’s a surefire way to miss a tight deadline!

When we need to hard anodize parts with tight tolerances, we like to send them to our preferred vendor in Chicago because they do such phenomenal work.

We recently had an order for 150 tiny parts that had through-holes with exceptionally tight tolerances. Our customer wanted the parts hard anodized, which we knew would grow the material. We reached out to our preferred plating shop in Chicago before quoting the parts to see if they could achieve those tolerances and discuss our machining approach.

We won the order and machined the parts according to the plater’s recommendations. We sent the parts to them to be hard anodized and they completely nailed it! All 150 parts came back to exactly the way our customer needed them.

Don’t rely on just any machine shop’s vendor supply chain. When you need parts with tight tolerances plated to perfection, send them to our Denver machine shop. Request a quote for your next project!