BLOG

How Long-Term Manufacturing Contracts Benefit Customers

If you find yourself placing repeat orders for the same parts multiple times in a year, consider establishing a long-term contract with your manufacturing partner. Not all shops provide contract manufacturing services, but those that do are almost always open to discussing this option with customers. That’s because long-term contracts benefit buyers and precision machine shops alike.

If you find yourself placing repeat orders for the same parts multiple times in a year, consider establishing a long-term contract with your manufacturing partner. Not all shops provide contract manufacturing services, but those that do are almost always open to discussing this option with customers. That’s because long-term contracts benefit buyers and precision machine shops alike.

Buyers benefit from better pricing, greater flexibility, and unbeatable consistency, while shops benefit from operational efficiency and the ability to predict their cash flow months in advance.

3 Benefits of a Long-Term Manufacturing Contract

Let’s say you need 100 parts for the year, but you want to spread that out into four deliveries of 25 parts, each spaced three months apart. Simply communicate this request to your precision machine shop and reap the benefits of a long-term contract.

1. Better pricing

The higher the quantity of parts you order, the lower the price per part. The shop has better purchasing power with material and plating vendors and can pass the cost savings on to you. More importantly, programming and setup—which can be time-consuming and costly—need only to occur once, and the cost is spread across many parts.

Think about it: if you have a complex part that requires three hours of programming and four hours of setup, totaling $700, and you only order one part, you're looking at an astronomically high price per part. Spread that cost across 10 parts, and your price per part decreases to $70. Now, spread that cost across 100 parts; your price per part is only $7.

Even in cases where the savings associated with programming and setup are minor—like if you're adjusting an order from 50 to 100 parts—many precision machine shops will be willing to reduce costs even further to account for the financial certainty they gain.

2. Greater flexibility

When you enter a long-term contract, the precision machine shop machines the entire order at once, ships you the parts you need immediately, and stores the rest of the inventory on their shelves. That means if you suddenly need your second delivery of 25 parts a month sooner than initially planned, the shop can easily accommodate your request. You get the flexibility you need without having to worry about placing costly rush orders.

3. Unbeatable consistency

There are many variables in the manufacturing process—from machining to plating—and the more those variables are reduced, the better the consistency is from part to part, from order to order. Even two different batches of parts that both meet print specifications will inevitably exhibit some variability, which can cause problems for buyers, especially when those parts go into complex assemblies.

When a precision machine shop has the opportunity to make 100 parts in one batch instead of 25 parts in four batches, buyers enjoy unbeatable consistency.

Is a Long-Term Contract the Right Fit for You?

It’s important to note that not all parts are suitable candidates for contract manufacturing services. If you can check these boxes, you could benefit from a long-term contract:

1. You authorize the shop to machine all the parts at once.

Machining all the parts at once is what allows shops to offer reduced pricing. The shop then holds the inventory on their shelves and ships the parts to you on a predetermined schedule.

2. You don’t anticipate revision changes.

Because shops must machine all the parts at once, long-term contracts are ideal for established parts and aren’t a good fit for parts in early engineering that may undergo revision changes.

3. You need a high quantity of parts.

The beauty of a long-term contract is that it’s mutually beneficial for both parties: buyers and shops. When the quantity of parts is too low, a shop doesn’t benefit much from the agreement. We can’t speak for all shops, but at Focused on Machining, we typically look for orders totaling a minimum of 100 parts over a year.

Start a Conversation about Contract Manufacturing Services

If you’re interested in discussing contract manufacturing services, let us know when you request a quote. It could be as simple as telling us, “I’d like to order 100 parts, but I’ll need them over six months.” We’re always willing to discuss the options with you and come to an agreement that makes everyone happy.

Don’t Let Cost Get in the Way of Selecting the Right Plating Vendor

One of the most important truths in manufacturing is that you get what you pay for—from production machining services to secondary processes like plating. Just as machine shops' costs and lead times vary depending on capabilities, certifications, and quality, so is the case for plating vendors.

One of the most important truths in manufacturing is that you get what you pay for—from production machining services to secondary processes like plating. Just as machine shops' costs and lead times vary depending on capabilities, certifications, and quality, so is the case for plating vendors.

A local anodizing house that doesn’t offer much in the way of certifications and quality control might charge $100 per batch and get parts done the same day. Fast and cheap is fine for a simple part with standard tolerances. But if you’re dealing with a tight-tolerance part for a mission-critical aerospace or defense application, you can’t afford to skimp on quality—and that means being open to higher costs and longer lead times.

The True Value of High-End Plating Facilities

We understand that customers appreciate having insight into what they’re paying for, so let’s take a look at how high-end plating facilities justify their higher costs and longer lead times.

High demand

There is often a large discrepancy between lead times at a local plating shop (1-2 days) and at a high-end, nationally recognized plating facility (2.5-3 weeks). That’s because the latter companies are in high demand, fulfilling orders from large government contractors that have them on their approved supplier lists. Generally, companies that are in high demand have excellent, well-earned reputations.

Critical certifications

Just like the best precision machine shops are ISO 9001:2015 and AS9100-certified, the best plating houses maintain NADCAP certification, a critical requirement for many aerospace and defense customers. Pursuing and upholding NADCAP certification can be costly, so it’s expected that NADCAP-certified plating houses charge higher prices. For example, a standard shop may charge a $100 lot fee, and a NADCAP-certified shop may charge up to $200.

Superior processes

While some plating processes are relatively straightforward, others, like anodizing, are highly complex and difficult to perform well.

Anodizers must monitor and control many factors, including the mix and ratio of chemicals and the temperature of the tank, to ensure high-quality results. Furthermore, because anodize adds buildup to material, anodizers must consider this additional factor when working with tight-tolerance parts where every ten-thousandth inch matters.

It takes a team of experienced chemists to develop the right processes to account for these factors. When a plating house isn’t up to the task, project timelines can easily become derailed—as we’ve learned the hard way.

You Get What You Pay For: A Real Example

Recently, 80 of 150 parts returned to us from an anodizing house exhibiting unsightly spots. We knew our best bet was to have the vendor strip the anodize and re-dip the parts, but previous experience had shown us that when plating houses don’t have their etching or stripping process dialed in perfectly, they remove too much material, and the parts end up out of tolerance.

We had the vendor strip the parts and send them back to us. Sure enough, they had removed too much material. Upon investigation, the vendor found that they had not only over-stripped the parts but also over-etched them early on. We had to make new calculations to ensure that the parts would be in tolerance, knowing the whole time that we might end up having to remake 80 parts from scratch if the plating house couldn’t get it right.

Losing weeks to the plating house’s missteps was a good reminder that you get what you pay for in manufacturing. Had we been able to send those parts out of state to a higher-end plating house for an extra $2 per piece, the order would have been delivered on time in perfect condition.

Don’t Get Caught Up on Dollars and Cents

We understand that time and money are critical considerations for customers seeking production machining services. But if we can offer one bit of advice from our experience, it’s not to get caught up on dollars and cents when negotiating costs. Doing so puts significant strain on shops to slash prices at the expense of quality. More often than not, both parties wind up losing out.

The truth is there’s a proper plating facility for every part, depending on its requirements. Allowing cost to get in the way of finding the right fit is a recipe for unmet expectations and unsatisfied customers.

If you’re on a tight budget, talk to us about what you need. In some cases, we may recommend an alternative plating process, like chem film in place of anodizing, that can get you the desired results without sacrificing quality. No matter what, we’re committed to finding a solution.

Request a quote for production machining services!

Why Our Precision Machine Shop Loves Source Inspections

Many shops view source inspections as a necessary evil. Source inspections can indeed be cumbersome for shops whose processes are still mostly manual—there’s no denying that. Fortunately, at Focused on Machining, our robust ERP system allows us to facilitate source inspections easily. In fact, we’ve even come to really appreciate source inspections and the customers who require them.

Many shops view source inspections as a necessary evil. Source inspections can indeed be cumbersome for shops whose processes are still mostly manual—there’s no denying that.

Fortunately, at Focused on Machining, our robust ERP system allows us to facilitate source inspections easily. In fact, we’ve even come to really appreciate source inspections and the customers who require them.

The Role of Source Inspections in Defense and Aerospace Machining

Source inspections are a common requirement among large aerospace and defense companies like Lockheed Martin and United Launch Alliance that deal with mission-critical parts. When a shop completes a precision machining order, the company will send a quality representative to its facility to confirm that the parts meet all specifications before they are shipped.

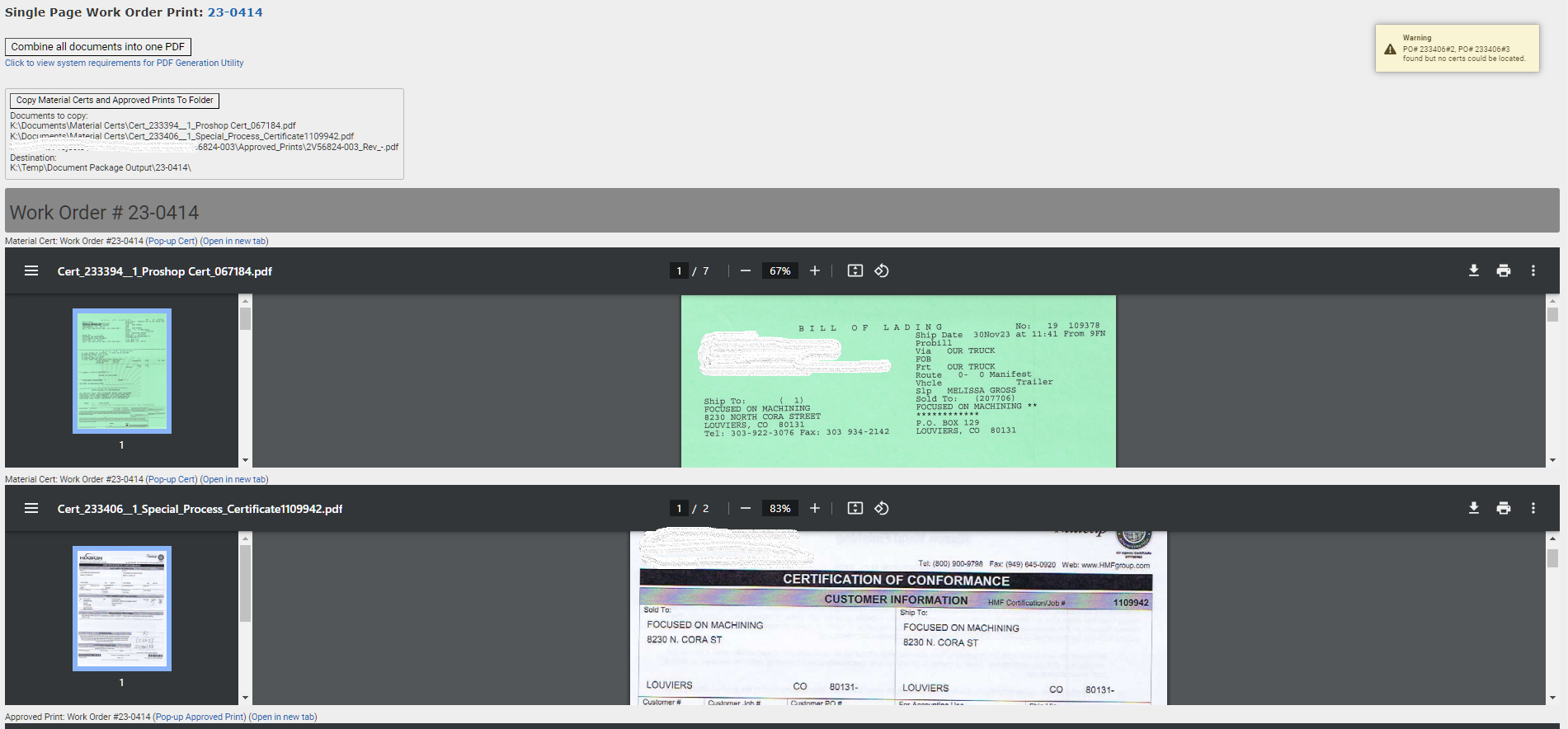

The source inspector will review the parts’ documentation (e.g., material certifications, plating certifications, print, inspection results) and conduct their own quality control inspections or ask the shop to demonstrate how their quality control team inspected the parts.

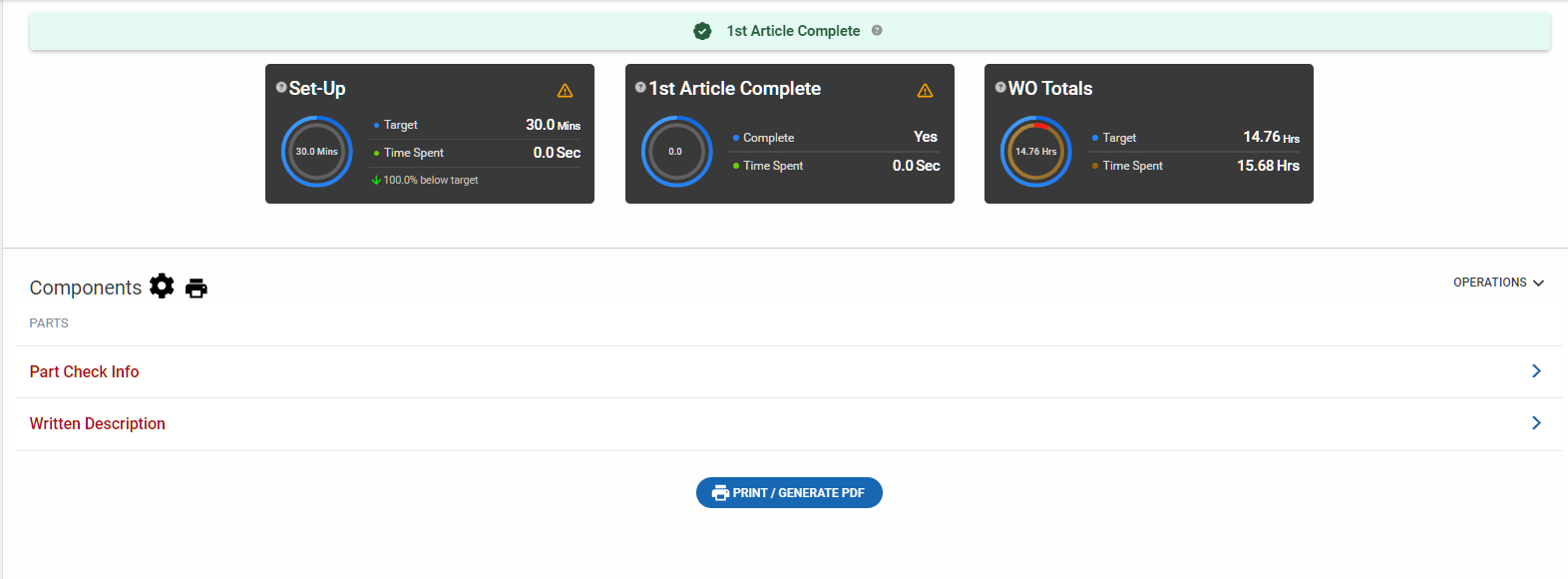

The goal is to identify issues proactively and prevent the lengthy back-and-forth that can occur when those issues are identified after the parts reach the customer. At Focused on Machining, we view this benefit as a win-win for shops and customers alike. While source inspections slow the process down initially, we appreciate knowing that once a source inspector has signed off on a job, those parts won’t return to us for additional work.

How Our ERP System Enables Easy Source Inspections

Documentation is an essential part of a source inspection—and that’s where many shops struggle.

For example, one of our customers requires that we upload our documentation to one website and use a different website to schedule a call. This company’s source inspector prefers to review the documentation virtually before coming for an on-site visit. We can then correct any issues so that by the time the source inspector arrives at our facility, chances are high that they’ll approve the parts that day.

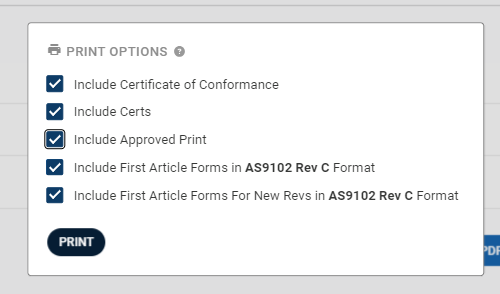

Understandably, shops with manual documentation processes can find it challenging and time-consuming to locate material certifications, plating certifications, prints, inspection results, and more and combine all that information in one neat package. But with our ERP system, this process is as easy as clicking a button. The system pulls the necessary information from different documents we’ve already uploaded and packages it together for us to save in a clearly labeled folder.

Source inspectors who have worked with our shop for defense and aerospace machining orders appreciate that they receive one file with all information organized in a sensible manner.

Want a Source Inspection? Let Us Know During Quoting

If you need a source inspection for your next defense or aerospace machining order, Focused on Machining is more than happy to accommodate you. We simply ask that you let us know during quoting so we can build a source inspection into our timeline and quote your lead time accurately.

Even if you don’t require an official source inspection, you’ll receive the same documentation package we deliver to companies that do. That’s because our commitment to providing stellar service extends to every customer we work with.

Request a quote for defense or aerospace machining services!

Could You Benefit from Contract Manufacturing Services?

Reducing the costs of machined parts can be as easy as having a conversation: always communicate with a shop about your purchasing intentions. If you plan to place a particular order on a recurring basis, the right contract manufacturing services partner can talk to you about opportunities to obtain the best costs over time with a long-term contract.

Reducing the costs of machined parts can be as easy as having a conversation: always communicate with a shop about your purchasing intentions.

If you plan to place a particular order on a recurring basis, the right contract manufacturing services partner can talk to you about opportunities to obtain the best costs over time with a long-term contract.

Here, we’ll review key considerations to get the most from contract manufacturing services and what to look for in a partner.

Considerations for Long-Term Manufacturing Contracts

Cost and delivery schedule

Costs vary depending on the buyer’s preferred delivery schedule. In the simplest terms, shops think about costs in three tiers:

Highest price = a low quantity of parts delivered immediately

Mid-range price = a high quantity of parts delivered in multiple shipments over a fixed period of time (e.g., quarterly)

Lowest price = a high quantity of parts delivered immediately

In other words, even if you can’t justify option #3, you can talk to your shop about option #2 and save money compared to option #1.

Potential for revisions

Some orders are a better fit for long-term contract manufacturing services agreements than others. An essential factor to consider before entering a contract is the potential for part revisions.

For example, suppose you agree to order 10 parts per month over six months with the understanding that the shop will machine all 60 parts at once and ship them from inventory. What happens if there is a revision change in that time? Who is liable for the parts that can’t be used: the shop or the customer? Most shops will clarify in their contracts that they can’t be held liable for engineering changes, leaving you to pay for parts you don’t actually need.

To avoid this risk, we recommend long-term contract manufacturing services for mature parts unlikely to undergo revisions.

But wait—if a part you plan to order on a recurring basis may undergo revisions, you still have options! In these situations, consider a blanket PO. When you submit a blanket PO to Focused on Machining, you agree to purchase X parts per month over Y months, but we won’t machine the parts all at once, giving you the opportunity to make minor revisions.

Blanket POs allow us to plan for the best (i.e., most cost-effective) path forward. For instance, we might design tooling and fixturing to improve efficiency or negotiate lower prices with material suppliers, leading to cost savings that we can pass on directly to you.

Assembly needs

Entering a long-term contract manufacturing services agreement is a perfect time to discuss your assembly needs. If we agree to deliver three unique parts in quantities of 10 every month, and those parts go together, talk to us about assembling the parts for you and shipping the complete assemblies.

What to Look for in a Contract Manufacturing Services Partner

As with any manufacturing engagement, vetting a shop before entering a contract manufacturing services agreement is important. Here’s what to look for in a partner:

Robust ERP system

A robust ERP system is essential to a shop delivering on its promises. At Focused on Machining, we schedule every job in our ERP system as soon as we receive a PO or enter a contract. When we tell you we can make X parts for you every month, it’s because we’re looking at our schedule and can confirm we have the machine capacity and resources to support that workload.

Regarding assembly work, our ERP system has excellent BOM capabilities to ensure we have every material, component, and more when we need it for even the most complex assemblies. That’s just one of the ways we maintain such a high on-time delivery rating.

In-depth contract review process

Big problems occur when shops don’t review contracts as thoroughly as they should. We’ve seen buyers burned by shops that take on contracts only to realize they can’t actually satisfy all the terms. The shops walk away from the contracts, and the buyers are left scrambling.

At Focused on Machining, we take the time to carefully review each contract to ensure we can deliver on all terms.

Superb inventory management

If you’re trusting a shop to hold inventory for you, you need assurance that their inventory management system is top-notch. The shop should be able to walk you through its approach to tracking and organizing inventory so you always know precisely what you’re getting.

One of the best ways to assess a shop’s inventory management capabilities, as well as other critical factors that make for a good contract manufacturing services partner, is to schedule a shop visit. Focused on Machining is happy to welcome you to our shop in person or via a virtual tour.

Contact us to discuss your contract manufacturing needs.

You Get What You Pay for in Manufacturing

You get what you pay for in manufacturing. Unfortunately, many buyers learn this lesson the hard way—something we’ve seen firsthand at our AS9100 machine shop. We’re happy to work with buyers now to get them the parts they need. But imagine the time, money, and stress they could have saved by having us machine their parts in the first place.

You get what you pay for in manufacturing. Unfortunately, many buyers learn this lesson the hard way—something we’ve seen firsthand at our AS9100 machine shop.

There has been a recent trend of buyers returning to Focused on Machining for parts we lost bids on months ago due to our “high” prices. The buyers selected cheaper shops but paid the ultimate price: poor quality, lost time, and costly rework. One is now six months behind schedule and under the gun to complete a critical project.

We’re happy to work with these buyers now to get them the parts they need. But imagine the time, money, and stress they could have saved by having us machine their parts in the first place.

The Importance of Vetting Suppliers

One potential reason for this trend is that buyers and suppliers aren’t arranging shop visits with the frequency they once did pre-COVID.

When visiting a precision machine shop, buyers have the opportunity to observe the shop’s systems, equipment, people, and processes. They get a good sense of what the shop can offer them, and the shop can instill confidence that they’ll get the job done right and on time.

Today, many initial conversations occur over the phone instead of in person, and buyers have less insight into what’s happening behind the scenes at a shop. Still, the right supplier should be not only willing but also happy to answer key questions to instill confidence in their work:

Does the shop have a robust ERP system?

Does the shop have a fully detailed scheduling module they can show you? (Trust us, not all scheduling modules are created equal.)

How does the shop arrive at their costs (i.e., what are their labor, quality, and overhead rates?)

What is the shop’s on-time delivery rate?

The Focused on Machining difference

In the case of our AS9100 machine shop, there is a lot going on behind the scenes as we quote jobs and prepare to make promises to customers in high-risk industries like aerospace, defense, and medical. These industries require (and deserve) the very best—and that’s what we deliver.

We develop fast, accurate quotes using Paperless Parts quoting software.

We look at our ERP system, scheduling module, and machines to assess open capacity and plan jobs.

We track material orders and calculate how long it will take for a part to undergo all necessary operations.

We follow strict processes with proven track records for success.

We’d be more than happy to walk you through our processes and give you a tour of our shop—either in person or virtually. Just let us know if that’s something you’re interested in!

Higher Costs = Higher Value

It’s true that our prices are often 15-20% higher than other suppliers—there’s no use denying it. But just as low prices come with hidden costs, higher prices promise hidden value. When you work with Focused on Machining, you’ll see that value in the form of the following:

On time delivery of your project

High quality, and a guarantee to correct any mistakes should they take place

AS9100 certification

Advanced software and processes, that enable us to achieve parts on time and at a high quality

Simply put, we have what it takes to get your parts done right the first time.

Tip: consider the total product cost

When you think holistically about your project and consider the total product cost instead of focusing too much on the price per piece, you’ll find that, in many cases, a higher price per piece yields a lower total product cost. Some of our customers learned that lesson the hard way, but you don’t have to.

The next time you need critical parts for a high-risk application, partner with an experienced AS9100 machine shop that will deliver the most value for your money. Request a quote from Focused on Machining.

The Importance of Investing in a High-Quality Prototype

We see it all the time: A customer wants an inexpensive prototype delivered as soon as possible, so they order one from an online marketplace. Everything seems okay at first, but eventually, they find out the hard way that when you choose the cheapest option, you get what you paid for.

We see it all the time: A customer wants an inexpensive prototype delivered as soon as possible, so they order one from an online marketplace. Everything seems okay at first, but eventually, they find out the hard way that when you choose the cheapest option, you get what you paid for.

The first sign of problems typically occurs when the customer needs to assemble the prototype into a product, and it doesn’t fit right. Or when they’re ready to start production, and the prototype hasn’t been optimized for fast and cost-effective manufacturing at scale. In some cases, the customer may not notice issues until much further down the line when a product wears out quickly or doesn’t perform as well as it should—all because they chose a cheap prototype over a quality prototype to save a little bit of money up front.

We can tell you from experience that if you plan to bring a prototype to production, your best bet is to work with a contract manufacturing services partner you trust from the beginning. Even if you invest more money initially, you’ll save time and money in the long run. The key is to communicate openly with the shop about your plans for the prototype so they can approach the project holistically and help you achieve your long-term goals.

Prototype-to-Production Case Study

Still not convinced? This real-life example might change your thinking.

Struggling to achieve the right fit during prototyping

A sheet metal shop customer of ours was tasked with creating a camera housing for one of their end customers. The sheet metal shop fabricated most of the parts in-house, with the exception of six tight-tolerance parts that had to be machined.

The end customer outsourced the machined parts to a precision machine shop, but when it came time for the sheet metal shop to add them to the assembly, they didn’t fit. They knew the parts hadn’t been designed or machined properly—possibly both.

The sheet metal shop elected to take matters into its own hands, convincing the end customer to let them choose a vendor for the machined parts and manage the relationship. They reached out to Focused on Machining to create prototypes of the machined parts, which would eventually be produced in higher volumes. But they thought our prototype pricing was too high. So, they turned to a less expensive precision machine shop.

Though the precision machine shop did a fine job on the parts, the sheet metal shop decided they wanted a local contract manufacturing services partner to maintain better control of the process and slash lead times. That’s when they reached back out to Focused on Machining.

This time, the sheet metal shop customer was more open to spending money upfront to save money in the long run. They had proven the concept with the previous shop and knew that if we could achieve the required tolerances, the parts would fit together perfectly. This is where clear communication between the customer and us was crucial.

Communicating openly to align on long-term goals

The sheet metal shop customer wanted a small batch of 25 parts each to start. They shared their target price per part for high-volume production while acknowledging that the price per part would be higher for an order of 25. They asked us to quote the batch of 25 parts however we needed to, but made it clear that they expected us to hit a lower price point eventually.

We happily agreed to these terms.

Quoting the initial 25-part order higher than the customer’s target price per part allowed us to spend time building the proper fixturing, which was essential for achieving the parts’ tight tolerances quickly and accurately.

We then calculated the maximum amount of precision machining time that would allow us to hit our customer’s target price per part and determined how to stay within that parameter. Our next step was investing in high-quality tooling, which was expensive but would enable us to achieve better speed and precision.

Finally, we ran the 25 parts and delivered them to the customer. Their response? “You guys make really beautiful parts!” The machined parts fit into the assembly perfectly with no issues. The end customer was thrilled and put in an order for 100 parts per month, which the sheet metal shop will outsource to Focused on Machining.

Because we were given the flexibility to put in the extra work during prototyping to perfect our process, we can now hit our customer’s target price point for high-volume production without a problem.

The moral of the story is…

…if you’re developing a prototype that you plan to transition to production, tell us your goals from the start. Let us do the prototyping at a cost that makes sense (yes—a higher cost than an online parts marketplace), and we’ll ensure that you’re wildly successful during production. The extra money you invest upfront will pay off in the long run.