BLOG

Material Spotlight: The Versatility of 6000 Series Aluminum

At Focused on Machining, we take pride in our expertise in precision CNC machining, which encompasses a diverse range of materials. Our skilled operators, paired with cutting-edge technology, enable us to produce high-quality parts from aluminum, steel, stainless steel, copper, brass, plastic, and more.

At Focused on Machining, we take pride in our expertise in precision CNC machining, which encompasses a diverse range of materials. Our skilled operators, paired with cutting-edge technology, enable us to produce high-quality parts from aluminum, steel, stainless steel, copper, brass, plastic, and more.

Among these materials, 6000 series aluminum has become a favorite among our customers, with aluminum 6061 leading as the most requested material at our shop. In this spotlight, we’ll explore the properties of 6000 series aluminum and share insights from our extensive experience machining these versatile alloys.

An Overview of 6000 Series Aluminum

6000 series aluminum is renowned for its strength, corrosion resistance, and formability. Its primary alloying elements—magnesium and silicon—create a unique combination of properties that cater to a wide range of applications.

When compared to 7000 series aluminum, which primarily uses zinc as its alloying element, 6000 series aluminum offers a different set of advantages. The 7000 series boasts a higher strength-to-weight ratio, making it particularly valuable in aerospace applications. However, this increased strength comes at a higher cost and presents greater challenges in machining. In contrast, the 6000 series provides an excellent balance of performance and affordability, making it a go-to choice for many industries.

The Benefits and Applications of 6000 Series Aluminum

6000 series aluminum alloys are not only easier to machine than many other alloys, but they also deliver an impressive strength-to-weight ratio. This combination of properties makes the 6000 series widely utilized across various industries, including automotive, construction, marine, aerospace, and beyond. These industries often demand tight tolerances and high precision, which is why selecting a machining partner who understands the nuances of these alloys is critical.

Another significant advantage of 6000 series aluminum is its compatibility with various finishing processes. This includes heat treatment, anodizing, chem film, painting, and nickel plating. At Focused on Machining, our extensive network of trusted vendors enables us to provide a range of finishing options for your parts, ensuring that they meet your specific requirements and industry standards.

Aluminum 6061: Our Most Requested Material

Among the 6000 series alloys, aluminum 6061 is particularly noteworthy and stands out as the preferred choice for many engineers and manufacturers. Its versatility makes it well-suited for a variety of projects, especially in applications where extreme conditions—such as high-temperature environments or the lightweight properties associated with titanium machining—are not a factor. Here are some key benefits of aluminum 6061:

Strength: With high tensile and yield strength, 6061 offers structural integrity suitable for many applications.

Lightweight: The alloy’s excellent strength-to-weight ratio is ideal for parts where reducing weight is crucial.

Thermal Conductivity: Compared to many other aluminum alloys, 6061 has higher thermal conductivity, making it frequently used for heat sinks.

Availability: 6061 is available in various forms, including rectangular bars, round bars, plates, and sheets, ensuring broad accessibility for manufacturing.

Machinability: Like many other 6000 series alloys, aluminum 6061 is easy to machine, which facilitates efficient manufacturing of customer parts.

Cost-effectiveness: It is one of the more economical metal options available, partially due to its high production volumes.

Trust Us With Your Next Aluminum Part

At Focused on Machining, our expertise with 6000 series aluminum equips us to tackle even your most challenging precision machining projects. Whether your part is in the prototype stage or moving into full-scale production, we are committed to being a trusted partner you can rely on for quality and precision.

We understand that effective communication and collaboration are key to transforming your ideas into reality. That’s why we invite you to reach out to us for a personalized discussion about your next aluminum component.

Request a quote today and discover how we can turn your vision into high-quality precision parts that meet your needs!

More Than Just Precision Parts: FOM’s Commitment to Customer Service

At Focused on Machining, customer satisfaction guides our actions every day and we’re constantly striving to elevate our performance. To measure our progress, we recently conducted a survey to gather feedback from our clients on key areas like customer service, product quality, and delivery times.

At Focused on Machining, customer satisfaction guides our actions every day and we’re constantly striving to elevate our performance. To measure our progress, we recently conducted a survey to gather feedback from our clients on key areas like customer service, product quality, and delivery times.

The survey results were insightful! We were thrilled to see that responses were overwhelmingly positive in every category. One area in particular stood out: our customer service. While we’ve always prided ourselves on providing excellent service, the feedback revealed that our commitment is not necessarily the standard; it's a defining quality that sets us apart in the industry.

Customer service is more than just a phrase to us—it’s ingrained in our company culture and shapes how we interact with our customers, vendors, and partners. Read on to discover how our dedication to exceptional service helps our precision machine shop stand out.

Quick Responses to Keep Your Precision Machining Projects On Schedule

Our responsiveness earned enthusiastic praise from customers. Many noted that they can expect a reply by the next business day. Swift communication is a point of emphasis for our shop, and we know that speed is essential in building trust with our customers and helping them maintain project momentum.

Clients also highlighted our commitment to acknowledging every RFQ, even if we cannot accommodate their project. Many other industry vendors do not respond to RFQs if the project is outside their capabilities or capacity. At Focused on Machining, we make it a point to respond to every RFQ. When we're unable to take on a project, our team explains the reasons to ensure transparency and maintain trust.

Solving Problems and Saving Lead Time With Attention to Detail

Attention to detail is another key differentiator in the feedback we received. Customers appreciate our ability to catch errors and oversights that had slipped past their team, including tolerance issues and feature callouts.

Other shops may flag these issues only during the machining phase, leading to costly delays and revisions. Instead, we identify and discuss any problems at the RFQ stage, collaborating with our customers to address these areas of concern early. This approach not only streamlines their production process but also reinforces our commitment to their success.

Why Customers Value Our Transparency

In our industry, gaining insight into your project’s status can be challenging, often leading to uncertainty about deadlines. AT FOM, we prioritize quick responses, with detailed updates on project status when requested. Transparency is especially critical in the rare cases when a project may face delays, and we always proactively reach out to discuss timing and possible solutions.

A recent experience perfectly illustrates our dedication to transparency and problem-solving. When an RFQ resulted in a price higher than we anticipated, we didn’t simply send the quote. Instead, we took time to research alternatives and double-check the calculations.

When the customer followed up, we told him that a specialized fastener included in the part had driven up the price of the order. He appreciated our transparency and quickly sent a purchase order, reaffirming the value of open communication.

The Best Email Addresses For Our Precision Machine Shop

Effective communication requires both attention to detail and structured processes. To meet our goal of providing timely responses, we have three dedicated inboxes at Focused on Machining, each designed for a specific aspect of your project. Multiple team members monitor these inboxes, ensuring that customer inquiries and concerns are handled promptly and efficiently:

rfq@focusedonmachining.com to submit RFQs or discuss quotes. (Note that our online portal is another option for RFQs.)

quality@focusedonmachining.com to submit questions on quality.

orders@focusedonmachining.com to send purchase orders directly to our order entry team.

Experience Our Commitment to Precision and Partnership

At our Colorado Machine shop, our mission is not just to deliver exceptional precision machined parts—we aim to be a trusted partner you can rely on. We understand the importance of fast responses, attention to detail, and clear communication to keep your projects on track and within budget.

Whether it's solving challenges early in the process or providing timely updates, we’re dedicated to supporting your success at every stage. You can count on us to deliver more than just parts—we deliver reliability and partnership.

Ready to work with a partner you can trust? Request a quote today and experience the Focused on Machining difference!

Custom Shipping Solutions at Focused on Machining

At Focused on Machining, our name reflects our precision machining expertise, but our focus extends far beyond that. Every step of the customer experience matters to us, from initial communication to machining to shipping. Delivering your parts on time and in perfect condition is a key part of our process. That’s why we’ve introduced custom foam packaging and reusable shipping crates for specific projects. This new shipping option offers better protection, more cost efficiency, and a smoother overall experience for our customers.

At Focused on Machining, our name reflects our precision machining expertise, but our focus extends far beyond that. Every step of the customer experience matters to us, from initial communication to machining to shipping. Delivering your parts on time and in perfect condition is a key part of our process. That’s why we’ve introduced custom foam packaging and reusable shipping crates for specific projects. This new shipping option offers better protection, more cost efficiency, and a smoother overall experience for our customers.

Elevating our Shipping Game

We produce parts for demanding industries, such as aerospace and medical, where precision is critical, and many parts require additional processing or testing outside our shop. For example, we frequently ship parts to trusted out-of-state plating partners.

In the past, we used standard foam for packaging, but that left a small risk of damage during transit, especially if the packaging was reused by a third party. While we’ve always taken extra precautions for high-value or delicate orders, these steps often increased shipping costs.

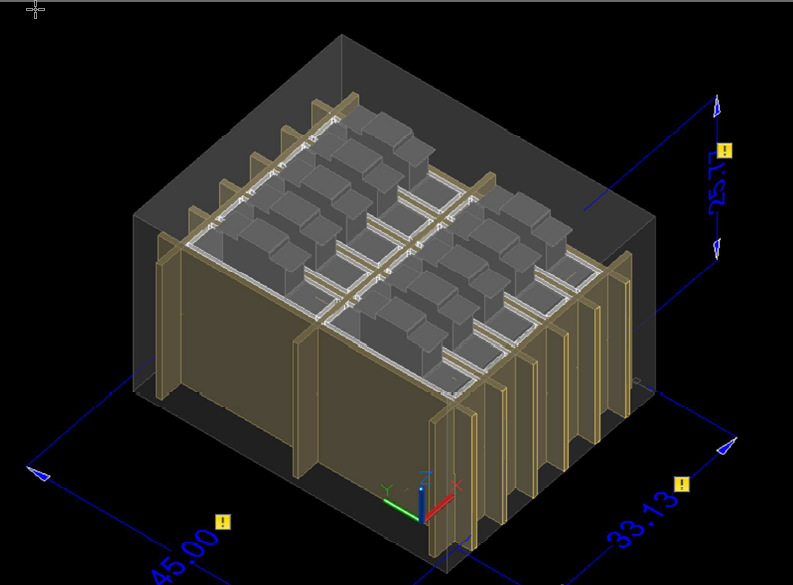

Now, we’ve taken a smarter approach. Our custom-cut foam packaging fits each part perfectly, and we use durable, reusable crates to further protect your parts during transit. This not only keeps your parts safe but also reduces costs and delivery time.

The Benefits of Our Custom Shipping Solutions

At our Colorado machine shop, we believe every detail matters. Here’s how our new shipping methods make a difference for you:

1. Cost-Effective Shipping

Custom foam allows us to securely pack multiple parts in a single crate, reducing the number of shipments needed. While the upfront cost of this packaging might be slightly higher, it ultimately lowers your overall shipping costs by minimizing packaging materials and consolidating shipments.

2. Faster Delivery Times

Fewer boxes mean fewer chances for shipment to be delayed. With the entire order packaged in one or two crates, there’s less risk of separate shipments falling behind, meaning your parts arrive faster and together.

3. Lower Risk of Damage

Shipping can be risky for parts with delicate features, unique geometries, or thin walls. Mishandling or rough transit can lead to scratches, dings, or even broken parts. Our custom foam packaging holds each piece securely in place, drastically reducing the risk of damage during shipping.

4. Better Customer Experience

For repeat projects, our reusable shipping crates streamline the process. Once you receive your parts, simply unpack the crate, apply the included return label, and send the crate back to us. We keep the custom foam on hand, so the next time we machine your parts, we’re ready to package them again quickly and efficiently. It’s a win-win for both cost and convenience.

What Projects Are Best Suited for This?

We evaluate each project individually to see if it’s a good fit for custom packaging. While these solutions are ideal for long-term contracts, they can also benefit low-volume CNC machining orders, particularly when the parts are:

Heavy or large

Delicate or thin-walled

Uniquely shaped or feature sharp angles

Expensive or single-order pieces

Partner with FOM for Smarter Shipping Solutions

At Focused on Machining, we are committed to providing you with the best possible experience—throughout the entire process, from quoting to machining to shipping. If you have a project, let’s discuss how our custom packaging solutions can ensure your parts arrive safely, on time, and cost-effectively. Reach out to us today to explore how we can support your next precision machining project!

From Air Force to Aerospace Machining: A Veteran’s Journey into Manufacturing

As Veteran’s Day approaches next month, I want to share the story of my journey from the Air Force to owning Focused on Machining, a precision CNC machine shop in Colorado. For many veterans, finding the right path after service can feel daunting, but I believe my experience can help offer a potential roadmap. My journey from military aircraft maintenance to running a manufacturing business has been deeply rewarding and I encourage veterans to explore opportunities in this field as they transition to civilian life.

As Veteran’s Day approaches next month, I want to share the story of my journey from the Air Force to owning Focused on Machining, a precision CNC machine shop in Colorado. For many veterans, finding the right path after service can feel daunting, but I believe my experience can help offer a potential roadmap. My journey from military aircraft maintenance to running a manufacturing business has been deeply rewarding and I encourage veterans to explore opportunities in this field as they transition to civilian life.

Embracing Service: My Early Days in the Air Force

Right after high school, I followed a long family tradition by joining the Air Force. Since I was a child, I felt the Air Force was my calling. As an aircraft mechanic, I was responsible for the C-17, the second-largest cargo aircraft in the Air Force fleet. Although the C-5 is technically larger, the C-17’s demanding missions gave it an edge, and I found that challenge exhilarating.

After completing basic training and a year of technical training, I became a crew chief. My role was to ensure that the aircraft were always mission-ready—performing inspections, overseeing maintenance, and coordinating with specialists. My three years in this position were filled with high-pressure deployments to Qatar, Turkey, and Baghdad, where I honed my skills and learned the true meaning of teamwork.

Going Global: Life as a Flying Crew Chief

After three years on the ground, I applied to become a flying crew chief—a role that took me all over the world. Anytime a C-17 flew to a base without dedicated maintenance personnel, I was there to ensure it was mission-ready. From performing emergency engine repairs in Kuwait after a bird strike to landing in snowy Afghanistan when I was packed for the 100-degree heat of Qatar, the experience was unpredictable and thrilling.

I’ll never forget being the sole mechanic on a humanitarian mission in Pakistan, waiting alone for hours in total darkness between C-17 arrivals, servicing each plane as it came. My time as a flying crew chief was filled with incredibly demanding situations - but they taught me resilience and adaptability. I spent three years traveling the world, a young guy in his twenties, living out of a suitcase and embracing each new challenge that came my way.

From Aircraft to Finance: Searching for My Post-Military Purpose

After leaving the military, I moved to Colorado, earned a degree in finance, and started working in banking. But it didn’t take long to realize that banking just wasn’t for me. The office environment couldn’t compare to the hands-on work I loved, and I missed the camaraderie and sense of purpose that came with the military.

My path to manufacturing began when I became involved with the National Tooling and Machining Association (NTMA). The people I encountered in local machine shops felt like a community where I truly belonged. Their work ethic and practical problem-solving were familiar to me from my time in the Air Force. I realized that many of the skills I had developed—blueprint reading, technical troubleshooting, and following precise processes—were a natural fit for this industry.

That’s when I decided to take the plunge and purchased Focused on Machining. It was a leap, but one that has brought me immense fulfillment.

Why Manufacturing Fuels My Passion

For veterans, manufacturing offers something truly special: a sense of purpose, teamwork, and the opportunity to continue serving in a different capacity. That’s why I’m so passionate about the work we do at Focused on Machining, especially in aerospace machining. The values I learned in the military—discipline, problem-solving, and teamwork—are the foundation of my company.

When I took over Focused on Machining, I made it my mission to achieve ISO and AS9100 certifications so we could handle the most complex aerospace projects. Some of the parts we machine are destined for the very military aircraft I used to maintain. Knowing that our work supports those still serving keeps me motivated every day. We approach each project with the same determination and precision that I applied during my Air Force days.

A Call to Veterans: Consider Manufacturing for Your Next Chapter

If you’re a veteran navigating the transition into civilian life, I strongly encourage you to consider manufacturing. It’s one of the few industries where you can translate your military experience directly into a fulfilling and challenging career. For me, it has been a way to bring the skills I learned in the Air Force into a new and rewarding chapter.

If you have a project—especially in aerospace—reach out to us at Focused on Machining. We bring the same dedication and passion to our work as I did during my time serving, and we’re always ready to take on your next challenge. Request a quote today.

Material Spotlight: 7000 Series Aluminum

At Focused on Machining, we bring years of expertise across a wide range of materials such as stainless steel, titanium, Monel and Inconel. Here, we’re focusing on our experience with 7000 series aluminum, a strong alloy that’s a popular material choice in a variety of industries.

At Focused on Machining, we bring years of expertise across a wide range of materials such as stainless steel, titanium, Monel and Inconel. Here, we’re focusing on our experience with 7000 series aluminum, a strong alloy that’s a popular material choice in a variety of industries.

An Overview of Aluminum 7000 Series

The 7000 series of aluminum alloys is among the strongest aluminum alloys available. It’s well known for its applications in aerospace and structural components. Because of our extensive experience in aerospace machining, we’ve grown very familiar with 7000 series aluminum.

7000 series aluminum has zinc as its primary alloying element, which differentiates it from 6000 series aluminum, another popular aluminum alloy that we often machine. The zinc content gives it high tensile strength properties, and its strength-to-weight ratio is one reason it’s so popular in applications like aircraft.

At Focused on Machining, we frequently work with several popular alloys from the 7000 series, with 7075 aluminum being the most common. This alloy is prized for its impressive strength-to-weight ratio, machinability, and the ability to further enhance its strength through heat treatment. We also regularly machine 7050 aluminum, another high-performance alloy in the 7000 series.

Among the drawbacks of 7075 is its limited corrosion resistance, which leads some engineers to choose 6000 series aluminum instead.

7000 Series Aluminum at Focused on Machining

We have been machining 7075 and 7050 for many years at our Colorado CNC machine shop, we sometimes feel like we’ve done it all with these alloys. Our customers see several benefits from our deep experience with 7000 series aluminum:

Speed: When a machine shop lacks experience with alloys like 7050, they often move cautiously, double-checking tooling and slowing down production. At Focused on Machining, we’re so confident in our expertise with 7075 and 7050 aluminum that we push our machines to their limits every time. This ensures that our customers receive their parts as quickly as possible without compromising on quality.

Price: We order so much of these materials that it’s unlikely any other shop can beat our pricing. We’re always getting the best prices from vendors because we have a long-term relationship with them and we’re ordering in such large quantities.

Processing: 7000 series aluminum often requires multiple post-processing steps and inspections. We have a trusted network of reliable aluminum processors who are experienced in working with these alloys. They are able to handle all of these processes under one roof, reducing lead time and minimizing the chances of any damage in shipping.

Knowledge: At certain times, there may be limited availability for a particular variety of 7000 series. For instance, maybe a customer asks for a large bracket in 7075 T6 six-inch plate, and we are not able to find it at that moment. However, we have the suppliers and the machining experience to find and machine it from T3 six inch plate or 7050 T6 six inch plate.

Talk to Us About Your Next 7000 Series Aluminum Project

At Focused on Machining, we’ve been making high-quality parts from 7000 series aluminum for years. We have the expertise to make what you need and the trusted partner network to get any post-processing steps done. And if you’re not sure if 7000 series aluminum is right for your project, we can offer some advice on selecting the right material for your CNC machined part.

Request a quote today to see how we can help with your next project.

How Quoting a “Family of Parts” Leads to Better Pricing

We’ve talked in the past about how long-term manufacturing contracts benefit customers in the right circumstances. And among long-term contracts, certain scenarios will offer even more savings. One of the most notable is working with us on a “family of parts,” a set of similar parts that we can machine at significantly reduced pricing.

We’ve talked in the past about how long-term manufacturing contracts benefit customers in the right circumstances. And among long-term contracts, certain scenarios will offer even more savings. One of the most notable is working with us on a “family of parts,” a set of similar parts that we can machine at significantly reduced pricing.

What Is a Family of Parts for a CNC Machine Shop?

A "family of parts" refers to a group of components that share common characteristics, such as material, size, features, and setup requirements. By standardizing these elements, we can optimize the machining process, reduce setup times, and minimize material waste. This approach not only increases efficiency but also enables us to pass on substantial cost savings to our customers.

When we are asked to quote a family of parts for a long-term contract, we can significantly improve on our standard pricing, because we can save on material and reduce setup time.

How to Identify a Family of Parts

For customers interested in this cost-saving strategy, it's essential to understand what qualifies as a family of parts. Here are the key factors:

Same Materials: Parts should be made from the same material, allowing for bulk purchasing and reduced costs.

Similar Size: Parts should have close dimensions to optimize material usage and machining efficiency. For example, if one part has a diameter of 0.75 inches and another is 1 inch, we can order material in a size that accommodates both.

Same Setup Fixtures: Using identical setup fixtures across parts significantly reduces setup time, speeding up the precision machining process.

Long-term Contract: Long-term commitments enable us to invest in fixtures and tooling, amortizing these costs over the contract's duration and further reducing expenses.

Quantity Requirements: The minimum quantity typically varies by project. We usually aim for at least 20 parts per quarter, with larger quantities yielding more substantial savings.

Cost Savings Through a Family of Parts

A recent project at our Colorado machine shop illustrates the benefits of this approach. A customer approached us with a three-year contract requiring the repeat delivery of approximately 60 parts per quarter. The initial request included 35 different part numbers made from various materials, including stainless steel, aluminum, carbon steel, and plastic.

By honing in on a family of parts as a subgroup, we knew we could offer drastically better pricing. We looked for parts of the same material that met the criteria laid out above and pared the order down to 21 parts. This subgroup allowed our team to find efficiencies and offer significantly reduced pricing, which the customer eagerly accepted. And because this was a long-term contract, we were able to take the time to create proper fixtures and optimize programming upfront.

However, it's essential to note that the quote was comprehensive. The improved pricing on a quote for a family of parts is an “all or nothing” proposition – we require customers to accept the entire quote rather than picking or choosing individual parts. The savings were contingent upon the entire order, enabling full implementation of cost-saving measures.

This example underscores the importance of providing detailed information when requesting a quote. The more context we have, the better we can optimize our processes and offer competitive pricing. Without detailed information, we might have quoted as if the parts were a one-time order, resulting in higher costs.

Talk to Us About Your Family of Parts

Partnering with Focused on Machining for a family of parts can lead to significant cost reductions. The potential savings often correlate with the complexity of the parts involved; the more complex the part, the greater the opportunity for cost savings.

If your next precision machining project includes a family of parts, we encourage you to reach out. Request a quote or contact us today to discuss how we can help you achieve better pricing and more efficient production. Our expertise and commitment to quality will ensure your project's success from prototype to production.