BLOG

A Proven Approach to Quoting Accurate Precision Machining Lead Times

When we quote you a lead time at Focused on Machining, you can be confident that we’ll meet it.

That’s because, unlike many shops that base their quoted lead times on instinct alone, our aerospace machine shop takes a much more strategic approach. Specifically, we leverage our ERP system to build a detailed schedule that accounts for many factors—from material sourcing and outside processing to our shop’s internal capacity.

When we quote you a lead time at Focused on Machining, you can be confident that we’ll meet it.

That’s because, unlike many shops that base their quoted lead times on instinct alone, our aerospace machine shop takes a much more strategic approach. Specifically, we leverage our ERP system to build a detailed schedule that accounts for many factors—from material sourcing and outside processing to our shop’s internal capacity.

The Nuances of Scheduling Precision Machining Jobs

Quoting a lead time requires us to consider the factors in our control (i.e., our precision machining capacity) and those outside our control (i.e., material sourcing and outside processing).

As you can imagine, the factors outside our control can be trickier to account for. The scheduling system we developed helps us with both.

Material sourcing and outside processing

When shops miss their quoted lead times, often it's because they failed to factor in shipping times. To avoid this issue, we enter the standard shipping time for each new vendor we set up in our ERP system.

If we’re sending parts across the state of Colorado for anodizing, the shipping time might be only one day. However, if we have to send parts out of state for a unique process like electropolishing, that’s a minimum of 2-3 days in transit (each way), which tells us we need to account for almost an entire week of shipping time.

The same logic applies when sourcing materials. If a material is in stock and the supplier is near our Denver machine shop, they might be able to get it to us in three days. If we need a material from a supplier in Arizona, we’re likely looking at closer to 5-7 business days.

Internal precision machining capacity

With our ERP system, we can look at work already scheduled on every machine in our shop to quickly answer questions like: What job is currently on X machine? How long will it take? When will X machine be free?

Sometimes, we identify a gap in the schedule. For example, we might see that the part we’re working on will finish next week, and the part scheduled behind it isn’t due for another month.

If a customer needs a quick turnaround on a prototype machining job, we may be able to move it ahead and still get all the scheduled jobs completed on time rather than blindly going in order. We can make these strategic decisions because of our diligence in entering the due date for each order and scheduling each machine individually.

How Our ERP System Calculates Accurate Lead Times

Although there are many factors to consider, calculating lead times is quite simple with our ERP system.

When we get a PO, we plug in the due date (the date the customer needs their parts) and other important details about the project. Because we have already entered the standard shipping times associated with materials and outside processes, the system will automatically subtract those days from the due date.

For example, if the parts need to be plated by a vendor in Kansas with a total shipping time of four days, the system will subtract four days from the due date.

We’ll then factor in how long it will take the vendor to plate the parts and subtract that time until we determine the actual number of days we have to complete our internal precision machining processes and the “must leave by date” (the date by which we need to send the parts to the plating vendor to ensure on-time delivery to our customer).

Accommodating expedited lead times

We also use our ERP system to quote expedited lead times. For instance, if a customer needs their parts in three weeks, and we know there will be one week of outside processing and shipping, we can arrange to pay the vendor an expedite fee to turn the parts around faster to meet the customer’s required due date. Understandably, our expedite prices are higher than our standard prices for this reason.

Mitigating Issues to Ensure On-Time Delivery

We proactively communicate with outside processing vendors to ensure they meet their quoted lead times, which is essential for keeping us on track for on-time delivery. However, material sourcing can be more challenging to manage due to the overall unpredictability of material availability.

A supplier may tell us they can get us a specific material in two days, and we’ll include that in our quote. But if the customer takes a couple of weeks to get us a PO, the material may no longer be in stock, potentially impacting our quoted lead time.

We encourage customers to submit POs soon after receiving a quote to avoid these outcomes. We apply this same sense of urgency when processing POs. When we receive a PO, we aim to have it entered into our system within one business day, which includes ordering the material.

If you’re unhappy with other shops’ lead times and on-time delivery rates, we encourage you to reach out to Focused on Machining. We can deliver most parts in 4-6 weeks, and when we tell you that, you can trust that we’re not pulling those numbers out of thin air.

Request a quote from our aerospace machine shop!

Industry Spotlight: Precision Medical Machining

Much like the aerospace industry, the medical industry has strict standards for precision machined parts. And while the AS9100 certification we possess here at Focused on Machining is specific to the aerospace industry, the processes we developed to maintain our status as an AS9100 machine shop enable us to meet the demands of the medical industry, as well.

Much like the aerospace industry, the medical industry has strict standards for precision machined parts. And while the AS9100 certification we possess here at Focused on Machining is specific to the aerospace industry, the processes we developed to maintain our status as an AS9100 machine shop enable us to meet the demands of the medical industry, as well.

4 Reasons to Trust Focused on Machining for Precision Medical Machining

Whether you’re nearby in Colorado or across the country, here’s why you should consider Focused on Machining for precision medical machining.

1. Material traceability

Material traceability is vital for medical parts inserted in the human body or used during surgery; there must be complete certainty that the materials have the necessary properties.

Focused on Machining guarantees material traceability throughout the entire manufacturing process, working only with carefully selected material vendors who provide accurate information, material specifications, and certifications.

2. Precision machining expertise

Medical parts often have intricate features, angles that are difficult to reach, tight tolerances, and high-precision surface finish requirements. A deep level of precision machining expertise is required to successfully manufacture these parts to specification.

Focused on Machining specializes in machining parts with complex features and has developed a reputation for our close attention to detail and superior quality.

We regularly machine stainless steel and acetal—two common materials used in precision medical machining. We’ve even put in the work to master more challenging materials—like titanium, a popular material for medical implants due to its durability, biocompatibility, and excellent strength-to-weight ratio.

3. Well-vetted electropolishing vendors

Parts used in medical environments must meet extremely high standards for cleanliness, and one way to achieve these standards is with electropolishing. This finishing method uses an electrochemical process to smooth a part’s surface, reducing and removing microscopic cracks and crevices that, if left untouched, could enable bacterial growth.

We machine many medical parts from stainless steel (known for its corrosion-resistant and bacteria-resistant properties), achieving a 32 or 24 Ra surface roughness. We’ll then send those parts to a trusted electropolishing vendor, who takes the roughness down to 10 or 8 Ra, which is essentially a mirror-like finish.

Focused on Machining facilitates coordination with vendors, taking on project management responsibilities to alleviate our customers of this burden.

4. Rigorous inspection process

We worked hard to improve our inspection process as part of our journey to becoming an AS9100 machine shop.

Each part is subject to a First Article Inspection, which means as soon as we finish an operation for the first time, we inspect the part thoroughly to verify that it’s in spec before moving on to the next operation.

If any adjustments are necessary, we cut another part (or re-cut the first part) and then re-inspect it. We document each inspection and maintain that documentation in our ERP system for historical purposes should we need to reference it at a later date.

We proceed through the manufacturing process until the parts are complete and inspect the completed parts per Acceptance Quality Limit (AQL) sampling standards. Upon customer request, we’ll inspect specific features on all parts—simply let us know what you need, and we’ll happily accommodate your preferences.

If parts require a plating process, such as anodizing or passivation, we outsource the service to a certified vendor and obtain the necessary certification(s) from the vendor to include in our quality documentation.

Get Precision Medical Machining Services

One of our primary medical customers builds testing equipment for artificial heart valves, and we make many of the parts for this equipment. We’re excited to take on more precision medical machining projects, especially with the numerous medical companies here in Colorado.

If you’re interested in our services, we’d love to hear from you. Request a quote, and let us put our expertise to work for you.

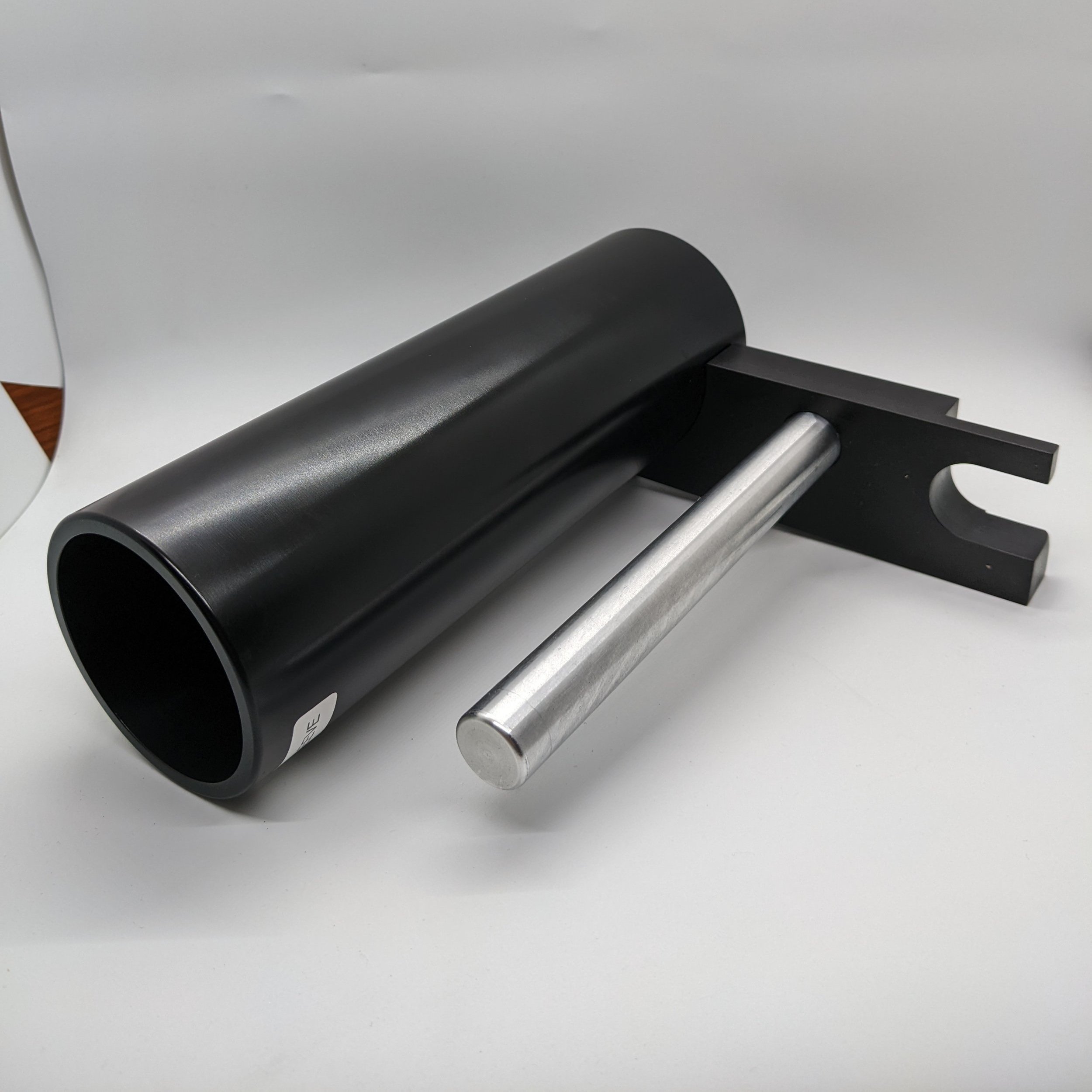

How Our Turnkey Assembly Services Benefit You

When you need an assembly, you have a couple of standard options:

Source the parts from multiple precision machine shops, and build your assembly in-house.

Source all the parts from one precision machining partner and have them build your assembly for you.

Last updated April 2025

When you need an assembly, you have a couple of standard options:

Source the parts from multiple precision machine partners, and build your assembly in-house.

Source all the parts from one CNC machine shop and have them build your assembly for you.

Buyers often choose option #1 because they assume it’s the most cost-effective solution. Maybe they source the complex parts from one shop and find a less expensive shop to machine the simpler parts so that they can secure the lowest total cost per part. Then they can have their own people assemble the parts in-house to save even more money—or so they think.

As a precision machine shop that has worked with many customers over the years, we have a different perspective on assemblies. We know the risks involved with sourcing assembly parts from more than one shop and that relying on a single shop for turnkey assembly services often saves customers time and money in the long run.

At Focused on Machining, we can:

Machine all the necessary parts for your assembly

Purchase and install hardware components

Rapidly build your assembly in our dedicated hardware assembly station

Ship it to you in perfect working condition

Guarantee full traceability on all of our hardware

Let’s explore some benefits of choosing us as your precision machining partner for completed assemblies.

Proactive Fit, Form, and Function Testing

Sourcing assembly parts from the same precision machine shop is especially important when parts require tight tolerance machining. For instance, if Part A fits into Part B, it’s possible that both parts could be machined to specifications but still not fit together in the final assembly.

If you source those parts from different shops, you won’t be aware of this potential problem until you receive the parts at your facility and can’t get them to fit. Now you’re going to lose time and money having the parts redone.

When you entrust one precision machining partner with your entire complex assembly, that shop can conduct fit, form, and function tests as they go, proactively fixing any issues to ensure that you receive a functioning assembly.

Hardware Purchasing and Installation

Machined parts aren’t the only factors to consider when building an assembly. There are also hardware components that must fit perfectly. A poor hardware fit or installation can result in a damaged part that could take weeks to get fixed. Fortunately, a full-service precision machine shop like Focused on Machining can purchase and install hardware for you.

Rivets

Rivet installation demands specialized expertise and equipment. With our advanced hardware assembly station, we’re equipped to handle high-volume rivet projects efficiently. Our tooling allows us to install large quantities of rivets quickly, which is particularly ideal for many aerospace machining projects.

Heli-Coils®

It’s easy to damage a threaded hole when trying to install a Heli-Coil. If that damage occurs at your facility, it could take weeks to get the hole fixed. However, if it occurs in our precision machine shop, we simply retap the hole, reform the threads, and properly install the Heli-Coil. In addition, our assembly station allows us to install Heli-Coils in seconds, while operations without the proper tooling may require five or even ten minutes per Heli-Coil.

Adhesives and Sealants

Some of our customers request that the inserts installed into their parts are sealed. In these cases, we can buy the adhesives or sealants, apply them properly, and install the hardware.

Trust Our Precision Machine Shop for Turnkey Assembly Services

Hardware purchasing and assembly require a trusted partner with rigorous quality control standards. As an AS9100 machine shop, we maintain complete traceability for all of our hardware components, sourced exclusively from certified suppliers.

When you trust Focused on Machining to provide turnkey assembly services, you significantly reduce the potentially costly risks associated with sourcing assembly components from more than one shop. You also free up your internal employees from having to build assemblies so that they can direct their labor elsewhere.

Still skeptical that you’ll save time and money with Focused on Machining’s assembly services? Let’s talk about your project. If you have an assembly you’d like to discuss, reach out, and we’ll let you know what we can do for you at our Colorado machine shop.

Material Spotlight: Copper Machining Services

Known for its high ductility and excellent electrical and thermal conductivity, copper is a popular material for applications ranging from rocket parts to electrical components.

Known for its high ductility and excellent electrical and thermal conductivity, copper is a popular material for applications ranging from rocket parts to electrical components.

However, many precision machine shops avoid working with this material. Copper is exceptionally soft, which creates challenges that make it difficult to machine:

Copper is hard to hold onto and can pull out of the workholding easily.

Copper tends to gum up and stick to cutting tools, so special coated tooling is required to machine this material effectively.

Fortunately, Focused on Machining never shies away from machining challenging materials. As demand for copper machining services increases, you can trust our aerospace machine shop to get the job done.

Copper: A Highly Conductive Material

Copper strikes a good balance between malleability and strength and possesses high corrosion resistance. But the property most sought after is its high electrical and thermal conductivity. In fact, copper is one of the most electrically and thermally conductive metals on the planet, second only to silver.

Capable of drawing heat away from other surfaces, copper is a great material for parts that will be housed near parts that generate heat. Many of our customers seek copper machining services for parts used in rocket builds—particularly engine components.

Grades of copper

Copper is available in various grades that fall under six categories: coppers (i.e., commercially pure coppers), dilute copper alloys, brasses, bronzes, copper-nickel alloys, and nickel-silver alloys. We commonly work with copper 101 and copper 110.

Copper 101 has no oxygen, making it highly electrically and thermally conductive and immune to hydrogen embrittlement at high temperatures.

Copper 110 has high electrical and thermal conductivity, good corrosion resistance, and is compatible with hot and cold working processes.

Why Choose Focused on Machining for Copper Machining Services

Focused on Machining has overcome the challenges associated with copper machining to provide superior copper machining services.

The right workholding

To prevent workholding issues, we use jaws designed to bite into the material. In fact, when quoting copper parts, we add extra material so we can use these jaws. As a result, customers get higher-quality parts.

The right tooling

Our commitment to mastering challenging materials yields excellent outcomes for our customers. Through our own trial and error, we’ve learned the best tooling, tooling coatings, and machine settings to use when machining copper parts.

The right suppliers

Because copper is a rare earth metal, supply can be limited. Fortunately, we have a wide network of material suppliers and excel at sourcing copper on behalf of our customers.

While it’s difficult for any shop to achieve precision tolerances when machining copper, we consistently hold standard tolerances of +/- 0.005” for copper parts. We are also capable of achieving high surface finishes, which is necessary for copper port parts requiring clean, flat surfaces for sealing. And if you need finishing services for your copper parts, we can coordinate options like electroless nickel plating and gold plating.

Request a Quote from Our Aerospace Machine Shop

When requesting a quote for copper machining services, we recommend planning ahead to account for the extra time that may be required to source your material. Due to sourcing challenges, it could take a few days for us to find the material you requested and a few additional days for us to receive it.

Keep in mind that not all grades of copper are readily available. Talk to us about your project, and we’ll gladly help you find the exact material you want or a comparable alternative.

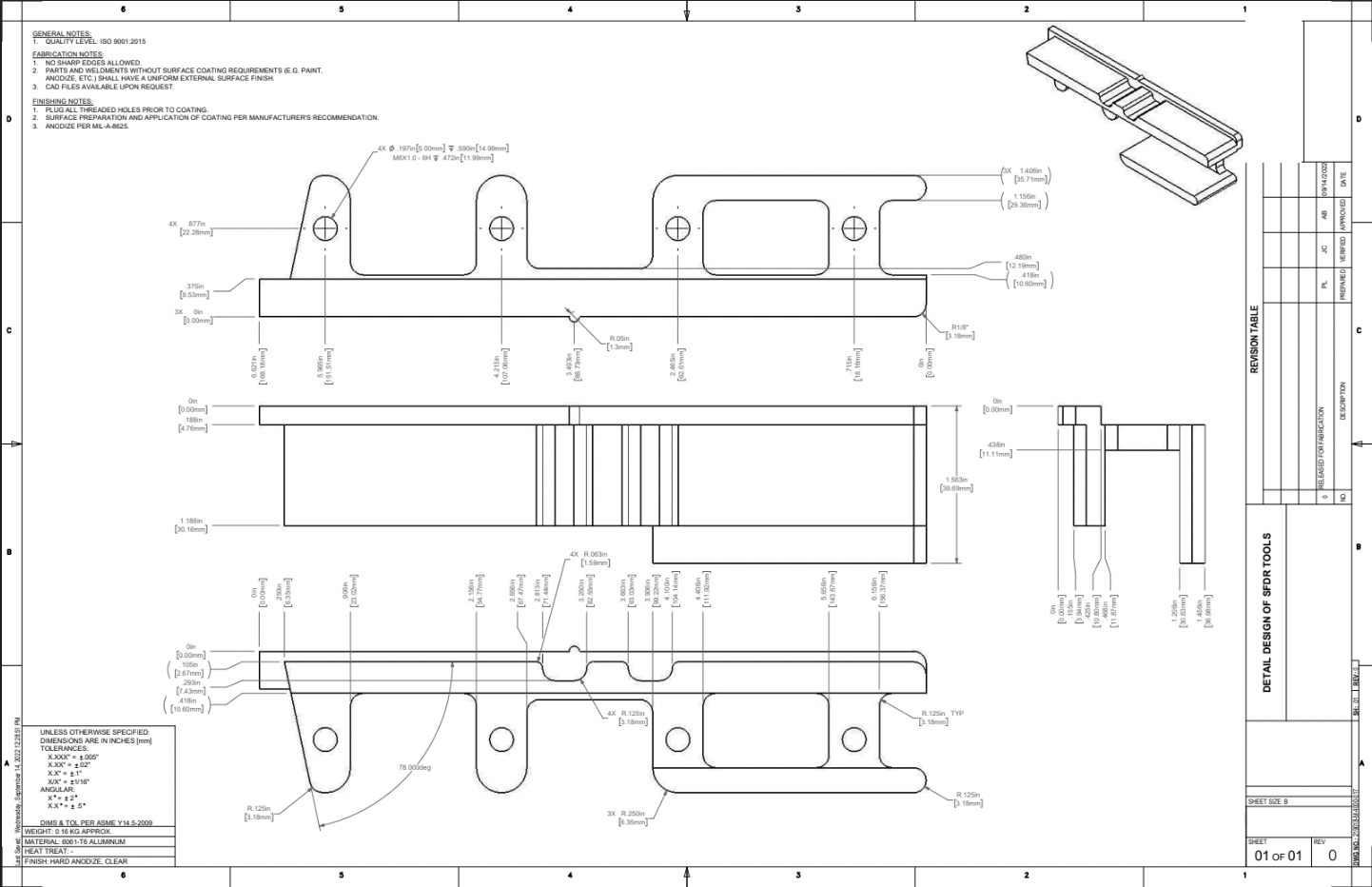

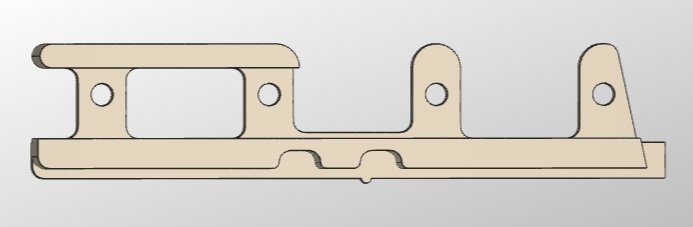

Why 3D Models Are Important in Precision Machining

When requesting a quote for precision machining services, it’s in your best interest to include a 3D model in addition to a blueprint. Both documents combined tell the complete story about a part, ensuring that customers get exactly what they need quickly and cost-effectively.

When requesting a quote for precision machining services, it’s in your best interest to include a 3D model in addition to a blueprint.

Both documents combined tell the complete story about a part, ensuring that customers get exactly what they need quickly and cost-effectively. Let’s explore why models are so crucial in precision machining.

Models Provide Critical Context to Ensure Part Accuracy

A blueprint provides essential details about a part’s features and each feature’s precise specifications. A model provides additional context that helps to clarify interpretive statements on the blueprint.

For example, an engineer might leave a note in the blueprint to “break all sharp edges.” However, the machinist’s interpretation of an edge break may differ slightly from the engineer’s. As a result, the engineer might not get precisely what they wanted.

In contrast, programming edge breaks into the model eliminates guesswork, giving machinists a clear 3D visual to add context to the specification from the blueprint.

3D Models Streamline Manufacturing to Improve Lead Times

Providing precision machine shops with a model in addition to a blueprint may feel needlessly cumbersome. But it actually streamlines manufacturing significantly, which is vital to many prototype machining customers seeking quick-turn manufacturing services.

Quick quoting

3D models empower us to turn around fast quotes using our digital quoting software. The software analyzes the model and automatically tells us important information about a part so that we can provide an accurate quote and get your project moving.

Simple programming

Our CNC machines and CMM inspection software use models to achieve auto-programming. For example, when it’s time to program a machine for a manufacturing operation, we can upload the model, click the features, add the tool paths, and get the operation started quickly.

Models Save Customers Money

We don’t machine parts without a model at Focused on Machining, so when a customer can’t provide a model, we need to create one in-house.

In these cases, we charge for our engineering time, which includes going back and forth with the customer over the course of a few days to make sure we’re interpreting the information on the blueprint accurately.

Our Advice: Always Include a 3D Model

For these reasons, we always encourage customers to provide models when requesting a quote for our precision machining services. We’re even happy to connect you with a freelance engineer who will develop a model for you at a fair rate!

We realize that some buyers have difficulty convincing engineers to grant them access to models. If you’re in this situation, it’s worth having a conversation with your engineering team. Be clear about how the absence of a model can negatively impact cost, lead time, and even quality.

Ready to get your project started? Request a quote from Focused on Machining—and don’t forget to include a 3D model if possible!

Your One-Stop Precision Machine Shop for Prototyping and Production

We’ve made a name for ourselves here in Denver, Colorado, as a reliable prototype machine shop serving industries including aerospace, defense, and medical. However, what many of our customers don’t know is that we also do low and even high-volume production work.

We’ve made a name for ourselves here in Denver, Colorado, as a reliable prototype machine shop serving industries including aerospace, defense, and medical. However, what many of our customers don’t know is that we also do low and even high-volume production work.

While precision machine shops often choose to specialize in small or large-quantity orders (instead of both), we know that many of our customers can benefit from partnering with the same shop for prototype machining all the way through to high-volume production manufacturing. And we want to be that shop.

Why Use a Precision Machine Shop for Prototyping and Production?

Here are some of the top advantages of choosing Focused on Machining as your one-stop shop for prototyping and production.

Unmatched efficiency

When you’ve already gone through prototype machining with one shop and choose to take your production order elsewhere, you’ll inevitably have people who have never made your specific part before trying to figure out how to do it.

Your prototype machining partner already has the answers.

Having worked out all the complexities during prototyping, we won’t have to take the time to learn your part. Even better—we’ll have all the fixturing in-house and can get your job programmed and set up much faster than a shop doing it for the first time.

Ultimately, we can move forward with incredible efficiency—and we pass that benefit on to you in the form of time and cost savings.

Consistent quality

Every precision machine shop has their own definition of quality. While many shops can build your part to print, you may notice small but obvious differences in aesthetics and functionality from one shop to another.

If you’re already happy with the quality we have provided you in a prototyping or low-volume capacity, it’s in your best interest to stick with us for higher-volume production.

Other shops might quote your project cheaper, but there’s no guarantee that you’ll receive the same level of quality. Let us know your price target, and we’ll do what we can to work something out.

Vendor consolidation

Starting anew with a vendor who has never worked on your part before can be a big logistical lift. By partnering with the same shop for prototyping and production, you have fewer details to iron out.

And that’s not the only way you’ll reap the benefits of vendor consolidation when you work with Focused on Machining. Part of being a true one-stop precision machine shop means project managing all secondary and outside processes for our customers, including plating, hardware installation, minor assemblies, and more.

We’ll coordinate every aspect of your project, from prototyping through production.

Low and High-Volume Manufacturing at Focused on Machining

From low-volume orders of 20-40 parts to mid-volume orders of 50-1,000 parts to high-volume orders of 1,000+ parts, Focused on Machining can handle your production needs. We can even manufacture orders in the 5,000-10,000 range. For orders larger than that, we’ll gladly connect you with another shop in the area we know and trust.