BLOG

It’s Time to Break the Cycle of Over-Tolerancing Parts

While a tolerance of +/- 0.0005” was once considered tight, we now regularly see prints with microscopic tolerances down to +/- 0.0001”. For visual context, a +/- 0.0003” tolerance is like taking a piece of hair, which is about 0.003”, slicing it into ten pieces, and having one of those pieces represent the permitted variance.

A recent trend in the precision machining industry is that customers’ tolerance requirements are becoming increasingly tighter.

While a tolerance of +/- 0.0005” was once considered tight, we now regularly see prints with microscopic tolerances down to +/- 0.0001”. For visual context, a +/- 0.0003” tolerance is like taking a piece of hair, which is about 0.003”, slicing it into ten pieces, and having one of those pieces represent the permitted variance.

Various factors are fueling this trend, but our goal here isn’t to get lost in speculation or finger-pointing. As a solution-focused aerospace machine shop, we’d rather take this opportunity to educate customers about this issue. Because at the end of the day, good communication between shops and customers is key to success.

The Problem with Inspecting Microscopic Tolerances

Achieving microscopic tolerances isn’t a precision machining challenge so much as it is an inspection challenge.

When it comes to quality control, shops have rules of 4, 7, or 10 dictating that the accuracy level of the inspection equipment should be 4, 7, or 10 times greater than the tolerance. So if there is a tolerance of +/- 0.0004”, and a shop is looking for 10 times greater accuracy during inspection, we’re talking about 0.00004”—or 1.3% the width of a human hair.

Only the most advanced inspection equipment in the world is that accurate. Many shops’ CMMs are only accurate to 0.0007” - 0.002”.

Are you getting the part you think you’re getting?

If a shop is tasked with creating holes with microscopic tolerances, they can buy the right tool, place it in the best tool holder, and create those holes perfectly. But when they go to check the holes, they could check them five times and get five different measurements. It’s impossible for them to say with certainty that the holes meet the customer’s specifications.

Maybe the shop’s inspection equipment can verify tolerances of +/- 0.0004” instead of the customer’s requested +/- 0.0001”. The shop will assume the part is acceptable and send it to the customer, but they can’t be 100% certain. And chances are the customer won’t have the ability to inspect the parts better than a CMM at a machine shop.

This common scenario isn’t doing anyone any good—not shops and not customers. Engineers will continue requesting unrealistic tolerances based on the (incorrect) assumption that the shop is meeting their requirements. Shops will be stuck taking on incredible risk to machine parts with rigid specifications without even being able to confidently verify that they got those parts right during inspection.

At Focused on Machining, we consider ourselves up for most challenges. (Case in point: our aerospace machine shop has mastered some of the most difficult materials.) But we end up no-quoting many parts with microscopic tolerances. Why? Because at the end of the day, we only want to take on projects when we’re 100% confident we can deliver what the customer asked for.

A Smarter Way to Approach Tolerances

Keep in mind that nine times out of ten, tolerancing is what drives up the cost of a part. So before calling out a microscopic tolerance on your print, ask yourself if it’s truly necessary for your part’s functionality.

The industry standard tolerances for specific features defined by the American National Standards Institute and the American Society of Mechanical Engineers are sufficient for many parts. The machinists at our aerospace machine shop follow those standards when consulting with customers about their parts, and we advise customers to follow them from the beginning.

For instance, these resources will have standard tolerances for something like an interference fit. You can feel confident that if you adhere to that standard, your part will function well and your shop will be able to meet your specifications quickly and cost-effectively.

At Focused on Machining, we’re always happy to collaborate with customers about the best approach to tolerances. We aim to set every project up for success, which means never promising something we can’t deliver and working with you to ensure you get what you genuinely need. Request a quote to work with us.

Why Our Machine Shop Always Confirms Receipt of POs

Have you ever placed an order online and checked your email inbox for a confirmation email, only to find nothing there? It’s a stressful experience. Without that confirmation email, you have no way of knowing for certain whether your order actually went through.

Have you ever placed an order online and checked your email inbox for a confirmation email, only to find nothing there?

It’s a stressful experience. Without that confirmation email, you have no way of knowing for certain whether your order actually went through.

This is one of the reasons people like shopping on Amazon: they know they can always expect an immediate confirmation email and regular updates about their order status. There’s no sitting around wondering about what’s happening behind the scenes.

Precision machining customers deserve a similarly transparent and seamless experience. That’s why, at Focused on Machining, we have a clear process for confirming receipt of all POs.

Our Process for Confirming Receipt of Precision Machining POs

When you submit a PO for our precision machining services, here’s what you should expect to happen:

We’ll respond with an initial email confirming that we received your order and are in the process of inputting it into our system.

We’ll respond with a final email confirming that the order is in our ERP system, material is on order, and the project is moving forward.

What should you do if you don’t receive either or both confirmation emails?

While our robust internal processes rarely let us down, any shop will tell you that miscommunications can and do happen, especially regarding PO processing. We set the expectation up front that we always confirm receipt of POs so that if, for any reason, you don’t receive either or both of the emails, you know to check in with us.

Here’s a general rule of thumb to follow: if you don’t receive an email confirming that your order has been placed within 2-3 days, reach out to us!

Best Practices for Submitting a PO to Focused on Machining

When you work with Focused on Machining, you might be in contact with various people in the time leading up to submitting your PO. Maybe you speak with an estimator after you request a quote or interact directly with our president, Justin Quinn. So, you might be wondering who to contact when you’re ready to submit a PO.

Here’s a general rule of thumb to follow: always submit POs to orders@focusedonmachining.com.

The simple reason is that multiple people on our team are checking this inbox throughout the day. Response times are fast, and the risk of your submission falling through the cracks is minimal. In contrast, if you send your PO to Justin, there’s a good chance he’s busy and might not be able to respond immediately.

When in Doubt, Communicate

When in doubt, communicate with us! We highly value communicating with customers and are never bothered when a customer checks in with us at any point in the manufacturing process. You deserve to know what’s going on with your project. Furthermore, we’re committed to being open and transparent about the status of your order—whether the news is good, bad, or somewhere in between.

We aim to establish an open communication policy with each customer from the get-go because good communication early on prevents issues down the line.

Request a quote to discuss your next precision machining project!

How Our Aerospace and Medical Machine Shop Keeps Lead Times Short

Never one to shy away from an opportunity, our aerospace and medical machine shop is committed to being the small shop customers need in this challenging climate. Keep reading to learn how we’ve improved efficiency to meet even the tightest deadlines.

Manufacturing lead times are getting longer, and this trend will likely continue as more small shops close down or are bought by bigger shops. On the flip side, today’s customers expect lead times to be shorter than ever—three weeks or less in our recent experience.

Never one to shy away from an opportunity, our aerospace and medical machine shop is committed to being the small shop customers need in this challenging climate. Keep reading to learn how we’ve improved efficiency to meet even the tightest deadlines.

Award-Winning Manufacturing Software Integration

When manual data entry was slowing us down, we knew it was time to integrate our quoting software and ERP system. So we collaborated with Paperless Parts and ProShop to develop a solution that would work not only for us but also for other shops.

Paperless Parts takes the data we initially enter, converts it accordingly, and sends it directly to ProShop for fast and accurate generation of estimates, parts, and purchase orders. ProShop then creates the purchasing requirements so we can quickly order materials and other necessary items.

It used to take us up to an entire business week to enter a PO and order materials. Now, when we receive a PO, we can have the material on order within 30 minutes. It’s not uncommon for us to receive the material at our aerospace and medical machine shop quicker than some shops enter an order into their system

Focused on Machining Wins NTMA and AMT’s Technology Excellence Award

We’re proud to say that our work helping to integrate Paperless Parts and ProShop won Focused on Machining NTMA and AMT’s Technology Excellence Award in 2023. The award recognizes member companies working to improve their businesses with advanced technology.

Eliminating Bottlenecks on the Shop Floor

We’re not only increasing efficiency at the front end of projects. We’ve also implemented measures to streamline operations on the shop floor.

Waiting on programming departments to program parts creates a bottleneck in many shops. To prevent this problem at our aerospace and medical machine shop, we’re training our machinists to become skilled programmers.

Now, when we’re in a rush situation, we can bypass the programming department entirely and have the machinist assigned to the part perform the programming.

We’re also brainstorming solutions for making our quality control process more efficient for tight tolerance parts, which tend to require time-intensive inspections.

Innovative Solutions to Real Industry Challenges

In an unpredictable industry, Focused on Machining strives to be a source of stability and reliability for our customers. We’re committed to continuously improving our internal processes to keep lead times short and customers happy.

Request a quote and let us know how we can support you.

Is Your Blueprint Setting You up for a Bad Assembly?

There’s no shortage of precision machine shops that will build a part to print without giving it a second thought. Don’t get us wrong; there’s something to be said for nailing all the specifications on a blueprint. But in many cases, simply adhering to a part’s specifications can lead to significant fit, form, and functionality problems. This is especially true when manufacturing parts destined for an assembly.

There’s no shortage of precision machine shops that will build a part to print without giving it a second thought. Don’t get us wrong; there’s something to be said for nailing all the specifications on a blueprint. But in many cases, simply adhering to a part’s specifications can lead to significant fit, form, and functionality problems. This is especially true when manufacturing parts destined for an assembly.

A Blueprint Doesn’t Always Tell the Complete Story

We’ve encountered numerous aerospace machining projects where a part’s blueprint doesn’t tell the complete story, though one recent assembly project comes to mind.

The customer contacted our AS9100 machine shop for a 3” diameter rotary shaft with a keyway cut and a separate ring that fits over the shaft and locks in via keystock. Their print indicated that we should purchase an off-the-shelf shaft with the keyway already cut into it; we would only need to perform some minor machining.

The problem was that the tolerances on the customer’s blueprint were tighter than those on the off-the-shelf shaft. If we were to follow their blueprint’s specifications, we would’ve had to make each of the units a perfect match fit consisting of a shaft, keystock, and ring that would only fit with each other. Not exactly ideal for a 70-unit assembly!

Upfront communication is critical in aerospace machining, so we contacted the customer immediately with our concerns and proposed an alternative solution. Instead of building the parts to print, we would build them with the bigger picture in mind.

We explained that in veering from the blueprint, we could guarantee that any of the rings fit with any of the shafts and lock in place with any of the keystocks. And we were right. We machined the parts and performed comprehensive test fits for verification before shipping the parts off to our happy customer.

When in Doubt, Talk to Your Aerospace Machining Partner

With that particular project, we could easily identify the problems presented by the blueprint because we were making all the parts for the assembly and knew what the customer expected from the final assembly. But that’s not always possible if, say, a customer sources an assembly’s parts from different shops. Or even if they source the parts from the same shop but fail to provide context on how the parts must fit together.

That’s why we like to tell customers: when designing an assembly, bring your aerospace machining partner into the conversation as early as possible. Tell them about your assembly and how the parts must interact with one another. Don’t wait for them to waste a few days trying to figure out a solution to a problem they’ve identified in your blueprint.

A good AS9100 machine shop can offer valuable advice to ensure your assembly fits and functions as intended. In many cases, our recommendations involve loosening tolerances depicted as unnecessarily tight on the blueprint. And because every decimal place adds a zero to the price, these recommendations can save you substantial money.

If possible, work with the same aerospace machining partner for all the parts in an assembly. When a shop has an opportunity to take a high-level, big-picture approach to your assembly project, you’ll ultimately benefit from a smoother process and better results. At Focused on Machining, we can even build your assembly and ship it to you ready to go.

If you have an assembly project on the horizon, we want to hear about it! Request a quote and tell us you’d like our support in finalizing the blueprint for your assembly.

Medical CNC Machining: Material Spotlight

Focused on Machining has built a reputation as a top aerospace machine shop. We love the work we do for aerospace and space customers. But we want anyone reading this to know that our expertise extends into another major focus area: medical CNC machining.

Focused on Machining has built a reputation as a top aerospace machine shop. We love the work we do for aerospace and space customers. But we want anyone reading this to know that our expertise extends into another major focus area: medical CNC machining.

Medical CNC Machining at Focused on Machining

While we don’t make parts that go inside the human body, we support the medical industry by machining parts for other critical applications, like testing equipment for artificial heart valves.

The capabilities and AS9100-compliant processes we’ve developed to serve aerospace customers directly benefit medical customers in key ways:

We guarantee material traceability throughout the manufacturing process

We specialize in machining tight tolerances and intricate features

We adhere to a rigorous inspection process for every part we machine

We regularly machine materials commonly used in medical applications

Common Medical CNC Machining Materials

Let’s closely examine three of the materials we encounter most frequently for medical CNC machining projects.

316 Stainless Steel

Sometimes called 316 surgical steel for its common use in medical applications, 316 stainless steel has excellent anti-corrosive properties due to its high nickel content. It’s ideal for medical parts that come into contact with liquid in their application or must be sterilized regularly. We can coordinate passivation services with a trusted vendor to further enhance corrosion resistance.

We also regularly send 316 stainless steel medical parts out for electropolishing services per customer request. Electropolishing smooths the part’s surface, reducing microscopic cracks and crevices to achieve close to a mirror-like finish. Smooth surfaces are critical for many medical applications because the smoother the surface, the fewer opportunities for bacteria to accumulate.

Aluminum

Budget-friendly aluminum can be a great alternative to 316 surgical steel for certain medical applications. It boasts excellent corrosion-resistant properties, enabling it to withstand frequent sterilization.

A significant benefit of aluminum is that it’s durable but notably lightweight compared to other metals and alloys. For this reason, it’s commonly found in products like trays and containers, hospital room equipment, and portable field equipment.

Acetal

This semi-crystalline thermoplastic rivals metals with its excellent strength, performance, and workability. As a slippery, low-friction material, it’s a great choice for parts with sliding mechanisms.

Acetal is relatively easy to machine, enabling medical machine shops to achieve tight tolerances and complex features accurately and efficiently. It’s also possible to achieve exceptionally smooth surface finishes with acetal.

The material has good chemical resistance properties and can be sterilized using various methods.

Make Focused on Machining Your Trusted Medical Machine Shop

If you’re looking for a reliable partner for medical CNC machining services, we hope you’ll consider Focused on Machining.

We have extensive experience machining 316 stainless steel, aluminum, acetal, and other materials used in medical applications. Let us put our expert team to work on your next project.

What to Know about Complex Masking Requirements in Precision Machinin

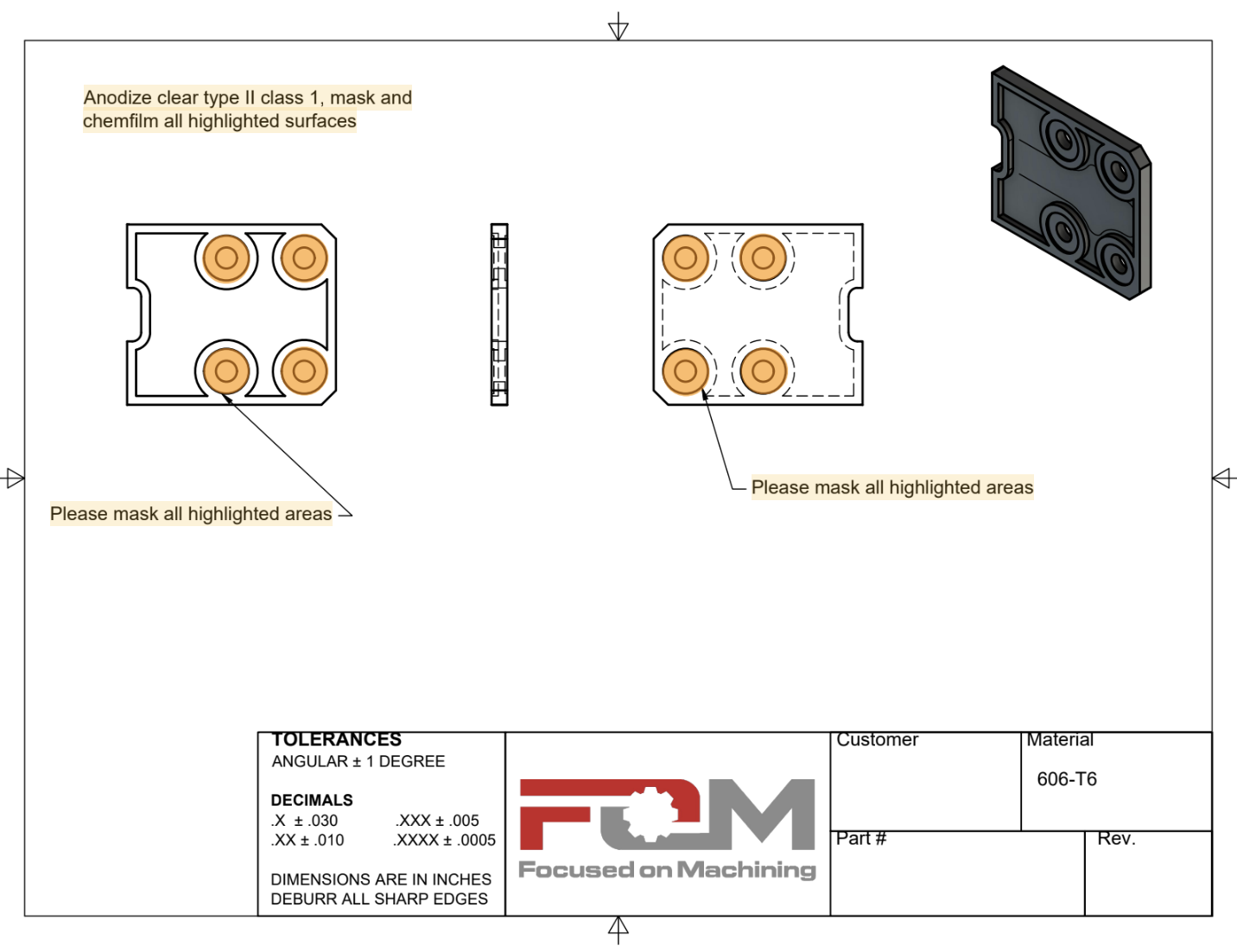

When shops quote customers high costs and long lead times for anodized parts, often it’s because the masking requirements are exceedingly complex. In some cases, complex masking requirements can double the price of a part.

Keep reading for our AS9100 machine shop’s insights into complex masking and tips for getting your parts faster and more cost-effectively.

When shops quote customers high costs and long lead times for anodized parts, often it’s because the masking requirements are exceedingly complex. In some cases, complex masking requirements can double the price of a part.

Keep reading for our AS9100 machine shop’s insights into complex masking and tips for getting your parts faster and more cost-effectively.

Complex Masking = Higher Costs and Longer Lead Times

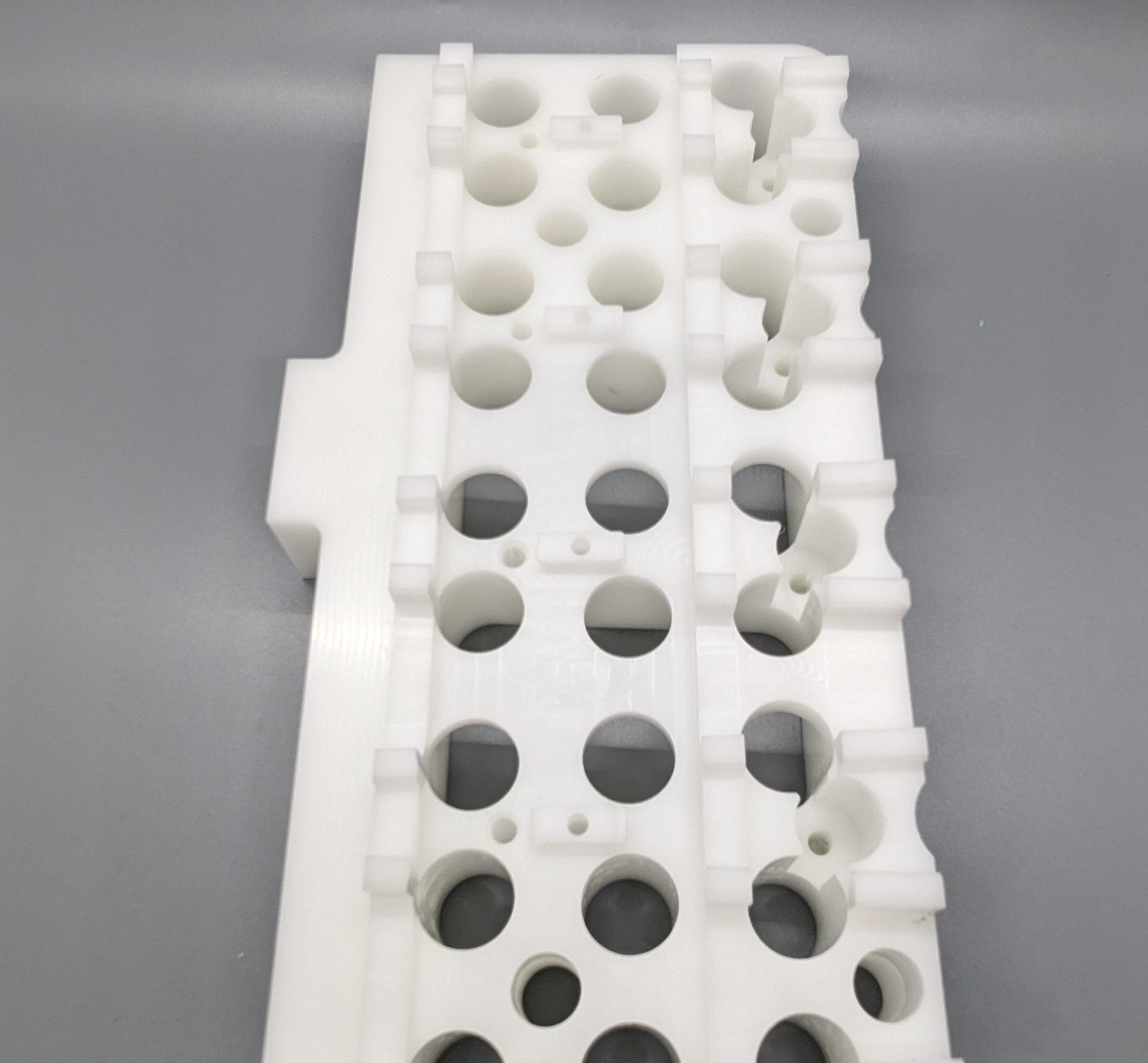

Masking is an entirely manual process that requires meticulous attention to detail. Flat, smooth surfaces are easy enough to mask. But when it comes to masking only a portion of a surface or small and intricate features, the process can be surprisingly time-consuming.

We once sent a lot of 15 parts to our trusted plating vendor, and it took them all day to mask just three parts. That’s not because the person doing the masking was slow or bad at their job. On the contrary, it’s because they’re great at their job and willing to put in the time and effort required to get it done right.

Since time is money in manufacturing, complex masking can add significantly to the cost per part. In this particular case, the plating vendor charged $300 per piece for the masking alone.

It’s worth noting that complex masking requirements can also cause delays during the quoting phase of a precision machining project. It can take an extra couple of days for a machine shop to receive an accurate estimate from a plating vendor.

Consider Chem Film to Avoid Complex Masking

As an AS9100 machine shop, we receive many anodizing requests from aerospace and space customers. Anodizing seals the surface of an aluminum part, providing a durable, corrosion-resistant coating that can withstand significant wear in extreme environments.

Because an anodized coating is electrically non-conductive, some of our space customers want certain features masked to maintain conductivity. While this request is completely valid, we like to encourage these customers to consider a chem film coating as an alternative to anodizing.

Like anodizing, chem film seals an aluminum surface and protects it from corrosion and wear. However, unlike anodizing, chem film helps conduct electricity. In other words, by selecting chem film over anodizing, space customers enjoy most of the benefits of anodizing without having to worry about costly and time-consuming masking.

Simplify Masking Requirements When Possible

We understand that customers whose parts require superior durability and wear resistance may not have the option of choosing chem film. In these cases, there are steps to take to simplify masking requirements.

When your objective is maintaining electrical conductivity, we recommend plugging threaded holes. It’s possible to achieve electrical conductivity through a threaded hole. And inserting a rubber plug into a hole is easier (i.e., faster and more cost-effective) than masking an intricate feature.

Another best practice is to mask large, smooth, flat surfaces instead of intricate features.

When You Need Complex Masking, Trust Our AS9100 Machine Shop

Can’t avoid complex masking? Don’t worry—Focused on Machining will make it happen. We just like to set clear expectations with customers about how complex masking can affect costs and lead times. It’s always a good idea to plan these projects well in advance.

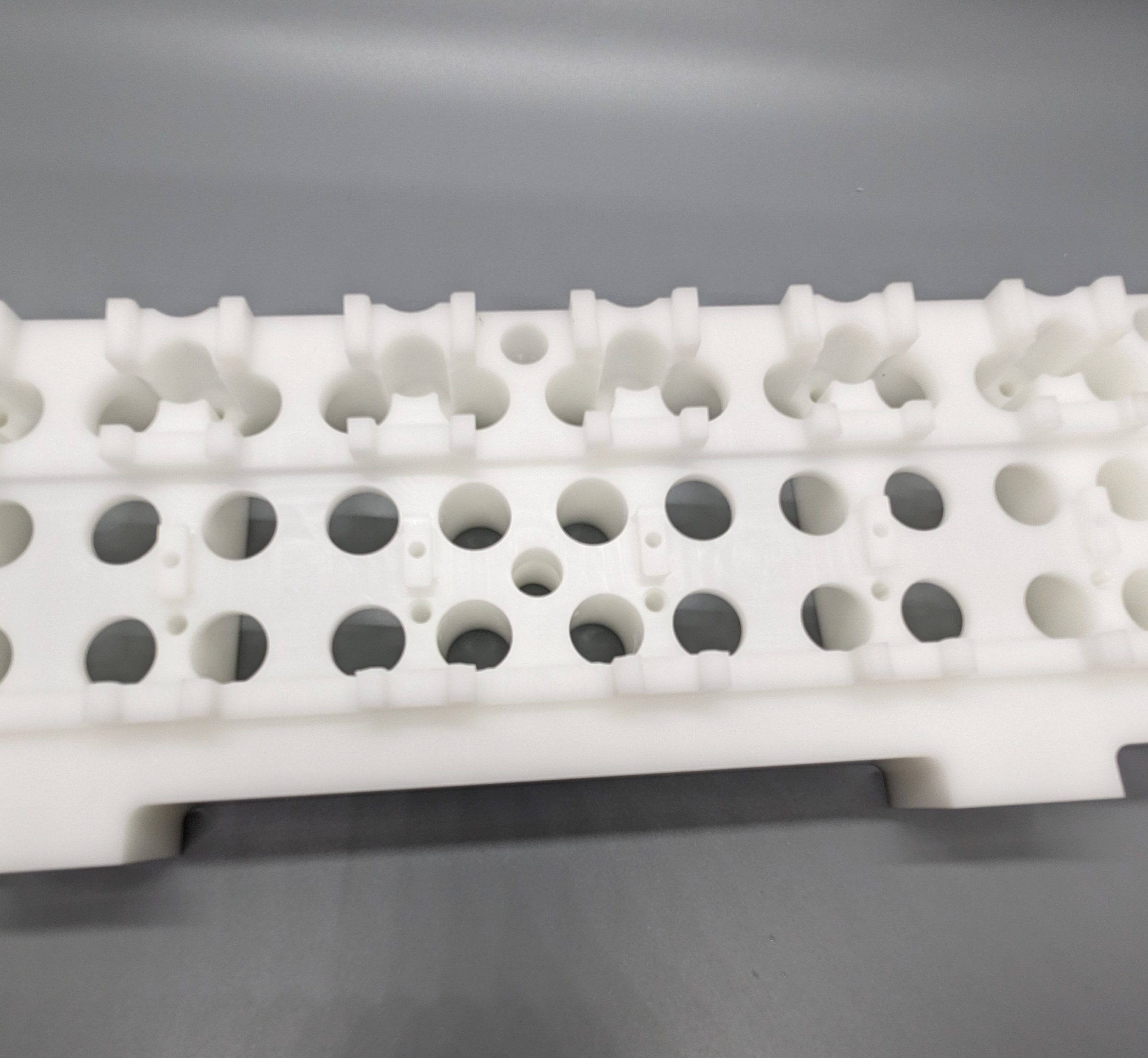

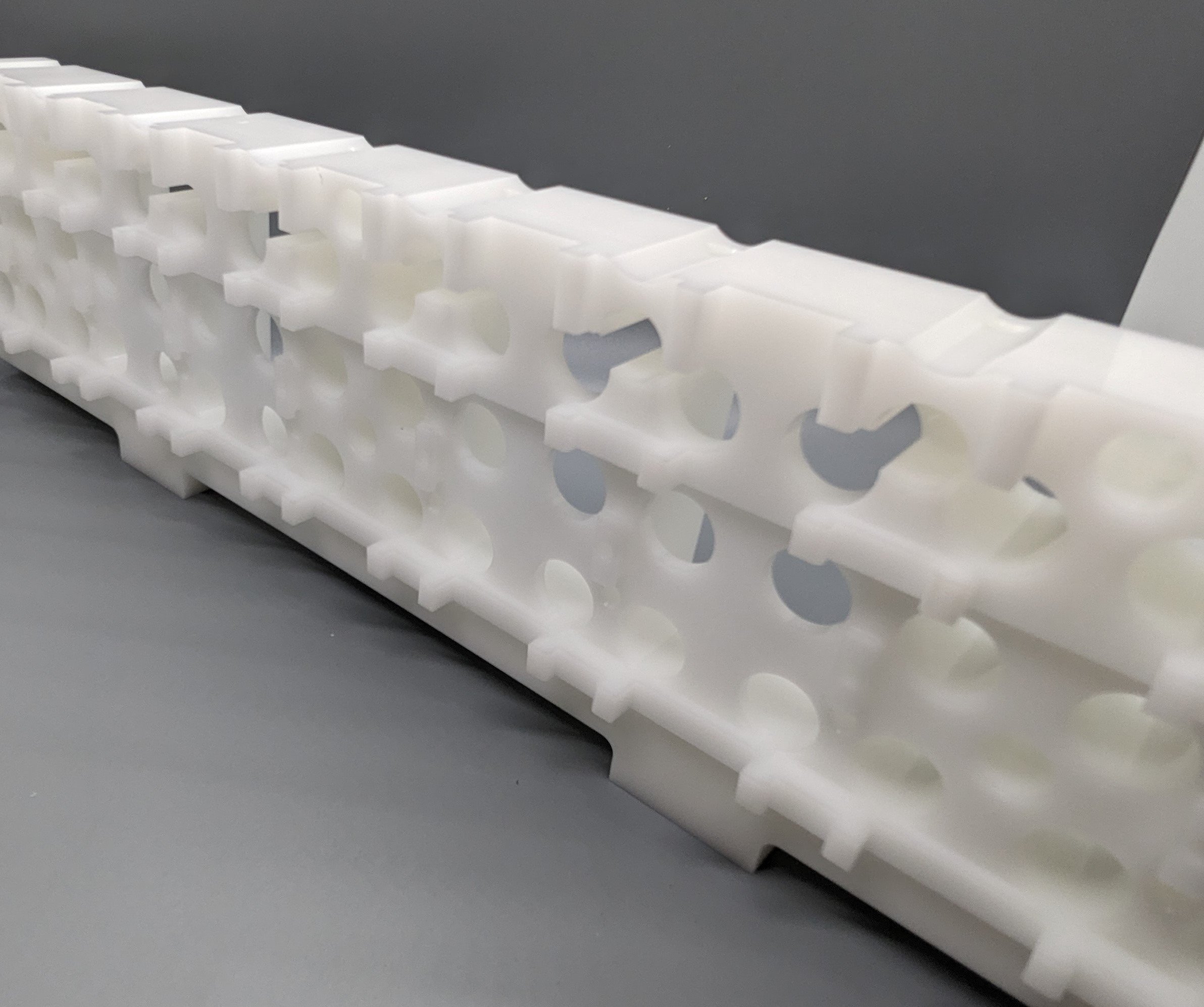

We have solid partnerships with some of the best plating shops in the country, and these shops specialize in complex masking. Over the years, we’ve refined our method for communicating complex masking requirements to plating partners. Our standard is to create our own masking prints that highlight areas requiring masking to make their jobs as easy as possible.

Request a quote from our AS9100 machine shop today!