BLOG

How Our Precision Machine Shop’s ERP System Streamlines Complex Assemblies

Building complex assemblies requires more than having the right capabilities and expertise on the precision machine shop floor. It’s just as important to have the right software working behind the scenes to facilitate the process.

Building complex assemblies requires more than having the right capabilities and expertise on the precision machine shop floor. It’s just as important to have the right software working behind the scenes to facilitate the process.

We recently wrote about how our advanced digital quoting software allows us to quickly turn around detailed and accurate quotes for complex assemblies. Now, let’s shift the focus to how we streamline the manufacturing of complex assemblies once we have a job. The secret is our ERP system, ProShop.

Controlling and Managing the BOM

The key to executing complex assemblies is controlling and managing the bill of materials (BOM). You may recall that our quoting software breaks up the assembly into three categories: manufactured components, purchased components, and subassemblies. Our ERP system does the same thing.

The BOM pictured shows that items 1-7 are individual parts. Then, there are corner wheel, lockout plate, pin block, and pivot plate subassemblies. The system will take each subassembly and break it up into its own more granular BOM.

Determining Purchasing Requirements

The ERP system will help us determine our purchasing requirements using the information from the BOM. For each purchased component, it will tell us a) the quantity we have in stock, b) the quantity we have on order, and c) the quantity already allocated to different work orders to come up with the precise quantity we need to purchase.

Creating Work Orders

The system will then create work orders for each manufactured component and subassembly in the assembly. The work order pictured depicts an aluminum 6061-T6 plate that needs to be hard anodized. No hardware is required because we aren’t yet at that point in the assembly.

When we have completed all 42 of these parts, we provide a final inspection, ship them to inventory, and move on to the next work order.

Maintaining Material Certifications

As any aerospace manufacturer is well aware, maintaining material certifications is critical. It’s hard to imagine how difficult that would be for a complex assembly without our ERP system.

However, fortunately, with the click of a few buttons, we can generate a list of the material certifications for every piece in the assembly—whether purchased or machined components. Pictured is an excerpt of a list that is probably hundreds of pages long.

Staying Organized to Keep Lead Times Short

While entering the information for a complex assembly into our ERP system can take a few hours, the upfront investment of time is well worth the effort.

Manufacturing a complex assembly requires an extremely high level of organization. When precision machine shops are disorganized, the process doesn’t run smoothly, and lead times tend to be long as a result. Our ERP system helps us stay organized from beginning to end so that we can complete and deliver complex assemblies quickly.

If you’re looking for a precision machine shop that won’t no-quote your complex assembly, bring it to Focused on Machining. We’ve got the right systems in place to confidently take on your project. Request a quote today!

To Succeed in Manufacturing, Learn to Thrive in Uncertainty

Running a precision machine shop during an industry-wide labor shortage, a global pandemic, unprecedented supply chain disruptions, and some of the most contentious presidential election cycles in history has certainly been one of the most interesting challenges of my life.

Running a precision machine shop during an industry-wide labor shortage, a global pandemic, unprecedented supply chain disruptions, and some of the most contentious presidential election cycles in history has certainly been one of the most interesting challenges of my life.

With another presidential election year underway, many CNC machine shops, including mine, are experiencing a period of decreased business as markets like aerospace and defense slow down spending while awaiting the election’s outcome.

In full transparency, Focused on Machining recently experienced three of the worst quarters on record. I don’t mind putting that in writing for all to see. Why? Because I’m confident we’ll persevere and that things will improve with time.

Focused on Machining has weathered plenty of storms and proven repeatedly that we come out better and stronger on the other side.

2018: Material Tariffs Lead to Pricing Volatility

When I took over as president of Focused on Machining on October 26, 2016, America was two weeks away from Donald Trump becoming president. It was a surprising outcome that most of us in manufacturing thought would positively impact our industry.

However, in 2018, President Trump announced that he would impose tariffs on steel and aluminum. Whereas previously, we could take POs without re-quoting projects, suddenly, we had to re-quote nearly every project due to material pricing volatility.

Instead of letting this obstacle get in our way, we began to identify and share material sourcing best practices with customers—best practices that would prove valuable amid the supply chain disruptions that would occur in the coming years. Additionally, I worked closely with the team at Paperless Parts to help them implement real-time pricing to automate the material quoting process.

2020: COVID-19 Pandemic Impacts the Global Economy

In March 2020, COVID-19 brought the world to a halt. Like everyone else in our industry, we wondered how it would impact manufacturing. I recall going through about six weeks of extreme uncertainty, fearing that a lack of business would lead me to inevitable layoffs.

Instead, the opposite happened: my business grew. As a CNC machine shop specializing in medical machining, we began quoting parts for 3D printed face shields, ventilators, and other equipment suddenly in high demand.

We then went on to experience our biggest growth period in history—right in the middle of the pandemic. While many shops did have to resort to layoffs, Focused on Machining found a niche with customers whose industries were booming during a time when people were spending a lot of their time at home: cannabis and beer canning.

2023-2024: Presidential Election Year Slows Business in Critical Markets

Recently, we’ve felt the impact as business has temporarily slowed in markets like aerospace and defense in anticipation of the 2024 presidential election. However, our efforts in the past decade have positioned us to continue thriving.

Here are just some of the reasons I know Focused on Machining is here to stay:

Continuous sales and marketing efforts help us stay top of mind for customers

Diversification across industries ensures we can navigate market highs and lows

Certifications like AS9100, ITAR, and ISO 9001:2016 allow us to cast a wide net

Willingness to take on complex projects means we manufacture parts and build assemblies other shops won’t

Fast quoting and on-time delivery build our reputation as a world-class shop, which helps us secure high-profile customers

I’m proud of how far Focused on Machining has come and excited to see where we go in the decades ahead. No matter what, I’m confident we can overcome any challenges in our way—we’ve already done that time and again, and the results speak for themselves.

How Our CNC Machine Shop Quotes Complex Assemblies Quickly and Accurately

Customers are often shocked at how quickly our CNC machine shop can turn around an impressively detailed and accurate quote for a complex assembly. Our secret? Our advanced digital quoting software. If you’re wondering what goes on behind the scenes, here’s a peek behind the curtain.

Customers are often shocked at how quickly our CNC machine shop can turn around an impressively detailed and accurate quote for a complex assembly. Our secret? Our advanced digital quoting software. If you’re wondering what goes on behind the scenes, here’s a peek behind the curtain.

Quoting a Complex Assembly

First, you’ll want to send us your full assembly file, which we’ll take and upload into our Paperless Parts quoting platform. From there, the software will automatically break up the assembly into three distinct categories—manufactured components, purchased components, and subassemblies—to provide an accurate quote.

Manufactured components

The platform will identify the components we’ll need to manufacture in our CNC machine shop and provide an estimate based on factors such as material cost, machine time, and plating.

Purchased components

Coordinating the ordering of the purchased components for a complex assembly can be challenging, especially for assemblies requiring dozens of unique components. Thankfully, Paperless Parts makes this task very simple.

All new components purchased for the first time are added to the system with the part number, description, piece price, and box price. The system automatically assigns the price based on the quantity of components needed.

Subassemblies

Complex assemblies typically involve multiple subassemblies. The software will break out the subassemblies, allowing us to determine which manufactured and purchased components go into which subassemblies and the amount of labor required.

Visual Example: Quoting a Modular Wi-Fi and 5G Signal System Assembly

A customer recently came to us with a complex assembly prototype that needed to be redesigned for added strength and durability. A couple of years ago, we would have no-quoted this customer outright because it would have taken too much time and effort just to quote the project. However, with Paperless Parts, we could provide a quote within just one day.

Looking at the BOM, you can see that many components are involved in this assembly.

But, here, Paperless Parts breaks everything down by subassemblies, manufactured components, and purchased components.

The information is broken down even further when we click on each subassembly.

Next Up: What Happens After Quoting

Of course, quoting a complex assembly is only the first step. Then comes the actual manufacturing. Fortunately, our advanced software streamlines the process from beginning to end.

Next month, we’ll dive deeper into what happens after quoting a complex assembly. Be sure to follow us on LinkedIn so you don’t miss the article. Ready to get your project started? Request a quote!

4 Tips for Sourcing Inconel Part

At our Colorado CNC machine shop, we primarily machine Inconel for rocket jet engine components. We’re adept at machining the many different grades of Inconel, though we mostly work with Inconel 625 and Inconel 718.

Since hitting the market in the 1930s, Inconel®—a group of nickel-based superalloys—has become a popular material for oil and gas, US Navy submarine, and jet engine components that benefit from its exceptional strength, corrosion resistance, and heat resistance.

Inconel has a low coefficient of thermal expansion at 77 degrees Fahrenheit to 1,400 degrees Fahrenheit, meaning it can withstand extreme heat and extreme temperature ranges without changing its size.

At our Colorado CNC machine shop, we primarily machine Inconel for rocket jet engine components. We’re adept at machining the many different grades of Inconel, though we mostly work with Inconel 625 and Inconel 718.

Inconel 625 vs. 718

Inconel 625 and 718 have slightly different compositions. Inconel 625 comprises nickel, chromium, molybdenum, and niobium, while Inconel 718 comprises nickel, chrome, iron, and niobium.

Both grades offer exceptional corrosion resistance, though 718 has a higher strength. Inconel 625 is generally easier to machine because although it is prone to chatter, it is not prone to work hardening to the same degree as 718. Work hardening occurs when worn-down tools mush the material, creating friction and adding heat, which makes the hard material even harder. Work-hardened Inconel 718 may become so hard that it’s nearly impossible to cut.

In other words, if your application doesn’t require the higher strength of Inconel 718, you can save money by selecting the easier-to-machine 625.

When customers ask for Inconel 718, our Colorado CNC machine shop typically works with AMS 5662 and 5663. AMS 5662 is the rawest and softest state of 718, which is how we prefer to machine it. AMS 5662 can be heat treated to 5663, a harder state of the alloy, though we wait until after machining it to bring it to this condition.

Need Inconel Parts? Follow These Tips

Getting parts made from specialty alloys like Inconel isn’t as straightforward as getting parts made from a standard material like aluminum. If you need Inconel machining, follow these tips for the best experience.

1. Work with a shop that specializes in Inconel machining

It takes a skilled machinist to effectively machine Inconel. With a material like aluminum, machinists can make big, deep cuts to remove a significant amount of material quickly. In contrast, Inconel requires smaller, lighter, faster cuts to avoid work hardening. Our Colorado CNC machine shop has mastered the art of machining Inconel.

In addition to meticulously cutting the material, shops must have the right tooling for machining Inconel. At Focused on Machining, we work closely with our tooling vendors to select tooling with special wear-resistant and heat-resistant coatings. We then dedicate that tooling exclusively to machining Inconel.

2. Be wary of the lowest quote

If five shops quote your Inconel job, and one shop quotes you significantly lower than the others, think twice before working with them. A suspiciously low quote often indicates that a shop might not have the proper experience machining Inconel to anticipate the challenges they’ll encounter with the material. In these cases, there’s a high risk that something will go wrong, delaying your lead time.

3. Anticipate material sourcing challenges

With materials in short supply, we always encourage customers to act fast by placing an order shortly after receiving a quote. This advice is especially important for Inconel, one of the more difficult materials to source.

4. Call out the right AMS specification

It’s not uncommon for engineers to call out a plate spec for a round part, prompting back-and-forth communication with a shop that can delay the start of the project. In most cases, engineers approve the use of a different spec, but by then, time has already been lost.

If you absolutely need a plate spec for a round part, we can use it, but keep in mind that your costs will increase because we’ll need to remove more material.

When you need Inconel machining, you can count on Focused on Machining. Request a quote today.

CMMC 2.0 Compliance Update from our Colorado CNC Machine Shop

Our Colorado CNC machine shop is in the process of pursuing CMMC 2.0 compliance, which will prove to the US Department of Defense that we meet rigorous cybersecurity standards. Now that we’re several months into the process, we’re here to provide an update on our status—because transparency and accountability matter to us.

Our Colorado CNC machine shop is in the process of pursuing CMMC 2.0 compliance, which will prove to the US Department of Defense that we meet rigorous cybersecurity standards.

To streamline the complex process as much as possible, we created a work order in our ERP system, ProShop, just like we would if we were manufacturing a complex part. The work order outlines a long series of steps to achieving CMMC 2.0 compliance.

Now that we’re several months into the process, we’re here to provide an update on our status—because transparency and accountability matter to us.

Our Progress Toward CMMC 2.0 Compliance to Date

As of March 2024, we’ve made significant progress through the Advanced Asset Inventory step in our CMMC certification work order. Here, we’ll provide insight into what each of these initial steps entails.

Introduction to CMMC and Resources - Complete

This step includes:

Reading through the CMMC 2.0 standard.

Understanding the certification levels.

Assigning a member of upper management to lead the implementation.

Informing employees of the process.

Documentation - In Progress

This step focuses on collecting all CMMC certification documentation and controlling who in the organization can access it.

Planning - Complete

This step includes:

Assessing whether the necessary resources are available to achieve CMMC certification.

Ensuring the entire organization is aware of the requirement.

Assessing how to allocate budgetary resources to necessary programs, platforms, or consultants.

Planning to achieve CMMC certification.

Assessing the available budget for implementing CMMC certification and the cost of becoming certified.

Appointing one staff member who is responsible for information security and can lead the implementation of CMMC.

Securing commitments from upper management to designate time and monetary resources for CMMC implementation.

Understanding the certification process, which involves arranging for a company that is part of the CMMC Accreditation Board to conduct an audit.

Identify Users - In Progress

This step includes:

Reviewing the definition of Least Privilege and understanding how it functions within the company. (Least Privilege ensures that users only have access to what they need to perform their job.)

Identifying all individuals in the organization with access to CUI systems.

Identifying all privileged and administrative accounts within all systems. (A privileged account is one with the ability to set configurations for all other accounts.)

Identifying all company positions within the organization.

Configuring the necessary access and training levels for each company position in our ProShop ERP system.

Assigning each employee a company position.

Defining the procedure for assigning company positions for employees who change roles.

Defining how users will be disabled once they are no longer employed.

Backups, Backups, Backups - 70% Complete

This step includes ensuring all platforms are being backed up. We’re working to document how our ERP system, ProShop, and our quoting software, Paperless Parts, manage backups.

Collecting Event Logs - In Progress

This step involves:

Creating and retaining system audit logs and records to the extent needed to enable the monitoring, analysis, investigation, and reporting of unlawful or unauthorized system activity.

Providing a system capability that compares and synchronizes internal system clocks with an authoritative source to generate time stamps for audit records.

Advanced Asset Inventory - 80% Complete

This step involves:

Creating a hardware asset inventory that includes the network address, hardware address, machine name, asset owner, department of the asset, and whether the hardware asset has been approved to connect to the network.

Creating a software asset inventory that tracks the name, version, publisher, and install date for all software on systems, including remote workstations.

Creating an inventory for other assets.

Identifying asset owners.

Goal: Achieve CMMC 2.0 Compliance by the End of 2024

We’re thrilled to say that our Colorado CNC machine shop is on target to achieve Level 2 certification, which has a long list of 110 requirements aligned to NIST SP 800-171, by the end of 2024.

Our effective approach to obtaining CMMC certification underscores what customers who work with us already know: our shop is organized, methodical, and strategic in the pursuit of any goal—big or small. We’d love to show you what we can do for you. Request a quote to work with us.

Zero-Point Fixturing: Our Approach to Complex Aerospace Machining Job

A recent trend in aerospace machining is that parts are becoming so complex that traditional equipment and approaches are no longer sufficient. Aerospace buyers often need parts with exceptionally tight tolerance features on opposite or multiple sides, which can be difficult to achieve with a standard CNC mill. At Focused on Machining, we’ve found great success leveraging multi-axis machining with zero-point fixturing to take on the most challenging aerospace machining jobs.

A recent trend in aerospace machining is that parts are becoming so complex that traditional equipment and approaches are no longer sufficient. Aerospace buyers often need parts with exceptionally tight tolerance features on opposite or multiple sides, which can be difficult to achieve with a standard CNC mill.

5-axis and multi-axis machining have emerged as gold-standard solutions for machining these parts, enabling shops to achieve the precision and efficiency required to feel confident quoting them.

At Focused on Machining, we’ve found great success leveraging multi-axis machining with zero-point fixturing to take on the most challenging aerospace machining jobs.

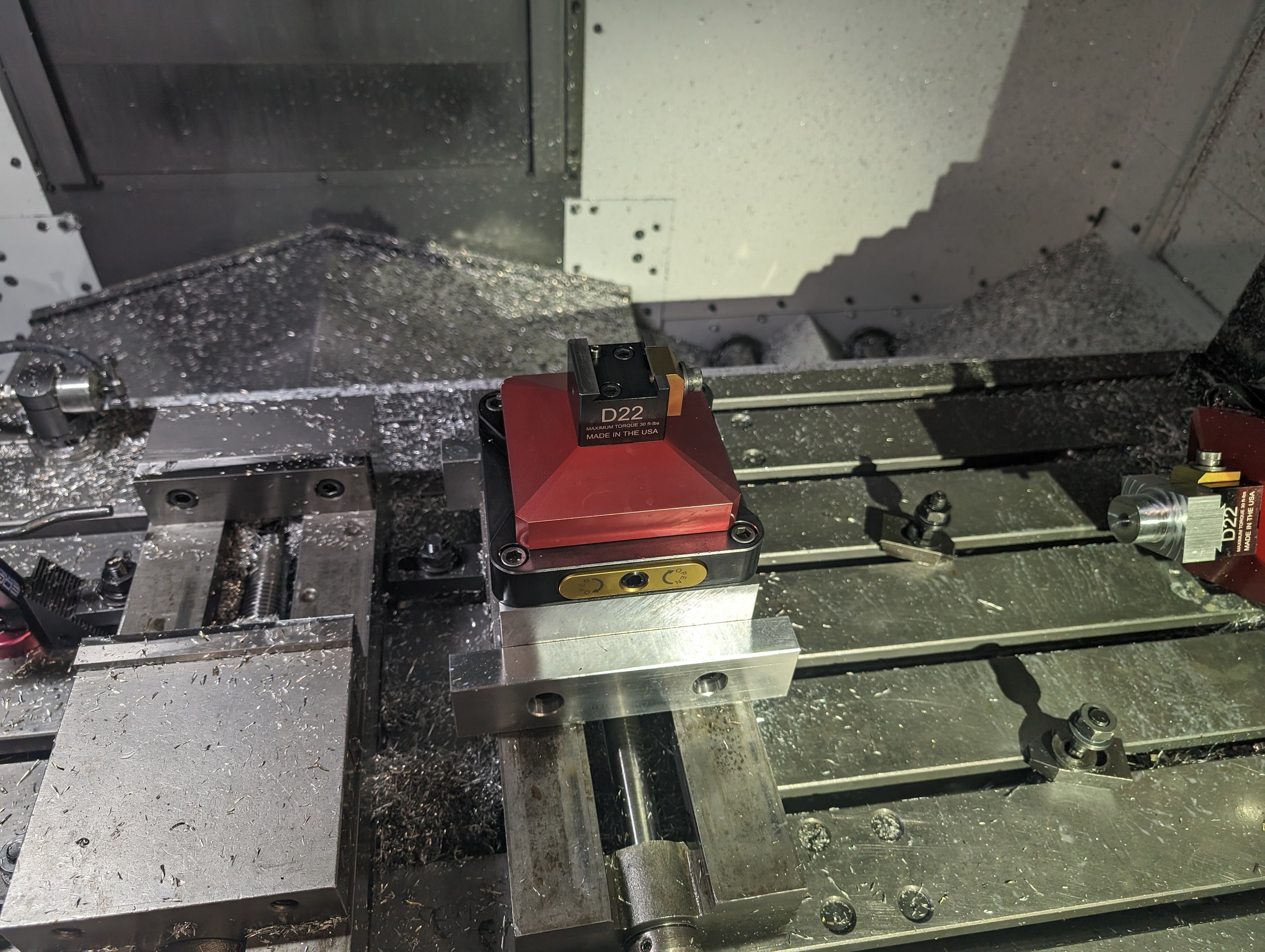

Our Shop’s Zero-Point Fixturing Solution

We invested in a RockLock base permanent fixturing setup for each of our multi-axis machines. The RockLock base allows us to swap vises and fixtures quickly with no setup time and guarantees repeatability of less than 0.0003”.

Here’s a comparison of how a complex aerospace machining job would proceed without zero-point fixturing vs. how it proceeds with zero-point fixturing.

Aerospace machining without zero-point fixturing

Let’s say we’re machining a tight tolerance part with three operations using a traditional setup without zero-point fixturing. Operation 1 is easy enough because we’re just machining raw stock to establish the datums from which Operation 2 and 3 will be measured.

However, once we get to Operation 2, things become more complicated. Let’s say we need to flip the part upside down or sideways to machine a different side. If the tolerances are exceptionally tight, the machinist will need to reposition the part and use a manual indicator to orient it perfectly in the machine. The machinist will then need to do the same thing with every single part in the order, which, as you can imagine, makes for an incredibly inefficient process.

This approach may be feasible if there are only 5-10 parts in an order. But most shops can’t justify having a machinist perform this degree of manual work for higher-volume orders—and the cost of doing so would make buyers’ jaws drop.

Aerospace machining with zero-point fixturing

With zero-point fixturing, the extensive manual work is eliminated. The vise enters a base that has pins in it with precise locating capabilities. We machine Operation 1 in that vise in one location to achieve all the Operation 1 features. Then, we take the entire vise up and out of the machine and move it to the Operation 2 fixture. The machine knows exactly where that part is within 0.0001” from Operation 1. No manual indicating is required, allowing us to work much more efficiently. Once we have proven the first part, we can machine multiple parts in the same setup.

Quality control

Even quality control is more efficient with zero-point fixturing. We have a RockLock base in our quality department, so if we program everything from the center of the vise—including the CMM—we can take the whole vise and part out of the machine, move it over to quality, and it will repeat there within 0.0001”. The quality department can run its program without spending time locating the part. If a change is required, we move the vise and part back to the machine and quickly make adjustments.

Meeting the Evolving Needs of the Aerospace Industry

As an AS9100 machine shop, Focused on Machining is committed to meeting the evolving needs of the aerospace industry. Multi-axis machining with zero-point fixturing allows us to take on complex jobs with the same precision and efficiency as 5-axis machining.

We love a good challenge, so don’t be afraid to approach us with your toughest aerospace machining requirements. Request a quote today!